Teaching

Resources

Research

The Precision Design Lab focuses on the following research topics: precision engineering, non-traditional machining of semiconductors, novel micro- and nanomachining, and biomedical instrumentation.

Current Research Projects

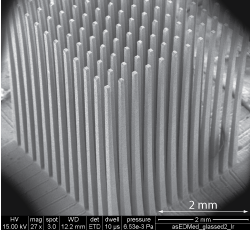

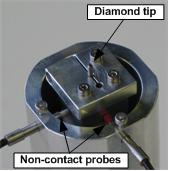

Fabrication of High-Aspect Ratio Silicon Microelectrode Arrays by Micro-Wire Electrical Discharge Machining A PZT Driven Micromachining Tool Based On Single-Point Tool Tip Geometry

Ph.D. project of Sumet Heamawatanachai

Volume Level Detection of Medical Samples in Opaque Test Tubes

Ph.D project of Xin Liu

Brendan Corbin, M.S. University of Utah, May 2007

Ph.D. project of Dinesh Rakwal

Past Research Projects

Piezoelectric direct drive 3-axis highprecision gimbal

Charles Tschaggeny, M.S. University of Utah, January 2008

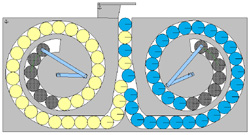

Drum-Type High-Capacity Magazines For 0.499 Caliber Ammunition For M-4 And M-16 Rifles

M.S. thesis project of Andreas Hellstrand

Design And Optimization Of An Integrated Gear Selector For Mountain Bikes

Benjamin Mann, M.S. University of Utah, December 2005

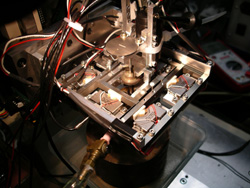

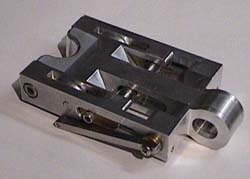

Flexural Micro-EDM Head For Increased Productivity of Micro-Holes

Sumet Heamawatanachai, M.S. University of Utah, November 2005

Design of the High-Capacity, High Caliber LW - 15 Stick Magazine

Clief Castleton, M.S. University of Utah, November 2005

Design of a Universal Belay Device (Patent Pending)

Nathaniel Young, M.S. University of Utah, November 2005

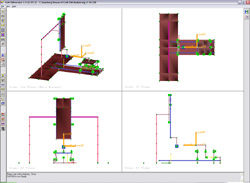

Conceptual Machine Design Simplification Modeler for Rapid Machine Design (Patent Pending)

Shreyas Hoskere, M.S. University of Utah, May 2005

Design Of An Internal Gear System For Bike Transmission Systems

Michelle Whiteside, M.S. University of Utah, May 2005

The existing prototype of the integrated gear selector works well for all but 2 out of 15 gear shifts. Whenever the chain has to be moved between the front chain rings, the rider needs to ease up on the pedals in order to allow the chain to shift (shifts that involve only the rear derailleur can occur under full load). The solution to this problem is an internal gear system based on a planetary gear box that can be shifted under full load as well.

Spherical Air Bearing Design

Yuchiang Lin, M.E. University of Utah, May 2005

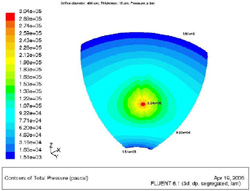

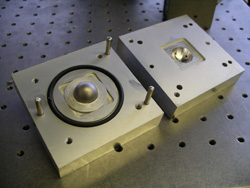

This project is based on the assumptions of a linear, non-compressible flow to analytically predict the flow rate, load capacity, and stiffness of spherical air bearings. The project investigated the use FLUENT to model such bearings and compare the results with experimental data.

Seamless Integration of Computer Aided Manufacturing (CAM) into the Mechanical Engineering Curriculum

Zachary Trimble, B.S. University of Utah, May 2005

Design Guidelines for Spherical Aerostatic Bearings

Dinesh Rakwal, M.S. University of Utah, January 2005

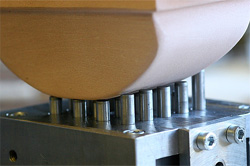

Design And Testing Of An Adaptive Machining Fixturing System For Surface Grinders

Xiaofan Xie, M.S. University of Utah, December 2004

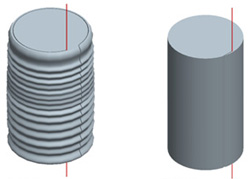

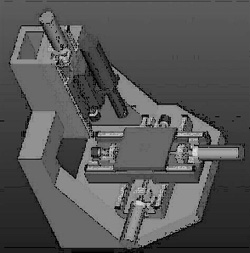

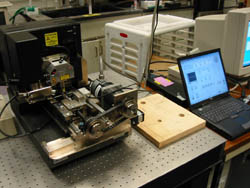

Design And Testing Of A Micro Machine Tool For Cutting Brittle Materials

Joerg Wiegelmann, Dipl.-Ing. University of Aachen, September 2004

Principles Of Precision Machine Design Applied To The Design Of A Desktop Milling Machine

Charan Sarjapur, M.S. University of Utah, August 2004

Christian Grippo, S.M. MIT, April 2002

A device used to apply and record stresses and strains in nano-composites while simultanously scanning the surface with an Atomic Force Microscope (AFM).

Eberhard Bamberg, Ph.D. MIT, May 2000

A 5-axis tool and cutter grinder for the manufacturing of solid carbide end mills. The novel base design of the machine is fabricated from round tubes.

Eberhard Bamberg, Alexander Slocum, MIT, 2000

A highly flexible constrained-layer damping design that is replicated in place through the use of expanding concrete.

Eberhard Bamberg, MIT, 1997

Designed as a lowcost, proprietary milling machine for the manufacturing of long, tubular workpieces.

Beam Bending Simulation

Eberhard Bamberg, MIT 2001

An educational tool used in the teaching of Mechanics at the Massachusetts Institute of Technology (MIT)

Eberhard Bamberg, University of Stuttgart, 1996

A 32-bit Windows application programmed in Pascal which predicts cutting forces in milling for various geometries and materials.

Eberhard Bamberg, University of Stuttgart, 1996

Dichteauswertung (32-bit Windows) is a tool used to analyze experimental data from cutting tests. The software reads in arrays of data generated from force sensors attached to the workpiece fixture and predicts the wear of the cutting edges.