Design Day - Fall 2016

Design Day is an opportunity to share our Senior Design Showcase with the public. Seniors work in groups with faculty to design and test projects.

Additionally, freshman and junior mechatronics’ students compete and showcase their skills.

Senior Design Projects

The Energy Systems Lab has a desire to reduce heating and cooling loads experienced by buildings. Solar radiation can provide a significant source of heat, which is desirable in cold weather but increases the cooling load during periods of hot weather. Therefore, we have designed an autonomous, intelligent window blind system to control the radiative heat flux. First, the blinds must be autonomous and intelligent which is what sets the product apart. Second, the blinds must govern the available solar radiation to help regulate room temperature by changing position. Third, the blinds must be user friendly and, finally, the blinds must be easily replicated and installed.

The Energy Systems Lab has a desire to reduce heating and cooling loads experienced by buildings. Solar radiation can provide a significant source of heat, which is desirable in cold weather but increases the cooling load during periods of hot weather. Therefore, we have designed an autonomous, intelligent window blind system to control the radiative heat flux. First, the blinds must be autonomous and intelligent which is what sets the product apart. Second, the blinds must govern the available solar radiation to help regulate room temperature by changing position. Third, the blinds must be user friendly and, finally, the blinds must be easily replicated and installed.

A rough analysis of the energy saving due to the blinds results in a savings of $120 per window per year. The projected system cost is $180 for the first window and $60 for each additional window. Therefore, the cost of the system could be recouped within the first year of implementation! (Automated Window Blinds Poster)

Team: Jarred Engelhom, Joe Lancaster, Michael Lybbert (lead), Cedric Shaskey

Advisors: Drs. Kam Leang, Amanda Smith

The aim of the Hydrogen Fuel Cell Vehicle Group is to explore hydrogen fuel cell technology as a viable alternative energy solution to the University of Utah’s needs. Specifically, to evaluate and reduce local campus emissions through the conversion of a fossil fuel powered University Fleet Services utility vehicle to hydrogen fuel cell power. (Hydrogen Fuel Cell Vehicle Poster)

The aim of the Hydrogen Fuel Cell Vehicle Group is to explore hydrogen fuel cell technology as a viable alternative energy solution to the University of Utah’s needs. Specifically, to evaluate and reduce local campus emissions through the conversion of a fossil fuel powered University Fleet Services utility vehicle to hydrogen fuel cell power. (Hydrogen Fuel Cell Vehicle Poster)

Team: Braulio Cuandon, Andrew Hurlbut, Christopher Landes, Nathan Mattison, Jeremy Villata (lead)

Advisors: Drs. Mathieu Francoeur, Amanda Smith

The NASA robotic mining team designed and constructed a robot to compete at the seventh annual NASA Robotic Mining Competition at the Kennedy Space Center. During the competition, the robot was tasked with driving to a specified area of the competition sand pit, mining regolith and gravel, and depositing mined material into a collection bin. This competition is meant to simulate a mission to Mars to mine ice beneath the planet’s surface. At the competition, the team placed seventh overall and won the Innovation Award for its design of a mechanism allowing the center of mass of the robot to remain constant as material is mined. (NASA Robotic Mining Team Poster)

The NASA robotic mining team designed and constructed a robot to compete at the seventh annual NASA Robotic Mining Competition at the Kennedy Space Center. During the competition, the robot was tasked with driving to a specified area of the competition sand pit, mining regolith and gravel, and depositing mined material into a collection bin. This competition is meant to simulate a mission to Mars to mine ice beneath the planet’s surface. At the competition, the team placed seventh overall and won the Innovation Award for its design of a mechanism allowing the center of mass of the robot to remain constant as material is mined. (NASA Robotic Mining Team Poster)

Team: David Denson (lead), Stacey Murguia, Teresa Petty, Geoff Sowan, Matthew Sheridan, Emily Herman

Advisor: Dr. Sanford Meek

The Table Tennis Club needs a serving machine that can operated by a single person in order to practice returning serves. This machine shoots a variety shots from different angles and locations while firing at different speeds with adjustable frequency. These shot settings are all determined by the controller which the user interacts with in order to manipulate the machine. The machine tracks its orientation and position relative to the table using encoders, infrared sensors, and a microcontroller. Multiple iterations of 3D prints have led to a more optimized design meant for fulfilling its objectives while remaining light and portable. New additions include a torsion spring working in tandem with a 70:1 gear motor in order to raise the firing chamber to a 45-degree angle for maximum distance. The torsion spring is critical in giving the motor the extra torque it needs to lift the firing chamber and keep it wherever it’s needed. (Shoot-o-Matic Poster)

The Table Tennis Club needs a serving machine that can operated by a single person in order to practice returning serves. This machine shoots a variety shots from different angles and locations while firing at different speeds with adjustable frequency. These shot settings are all determined by the controller which the user interacts with in order to manipulate the machine. The machine tracks its orientation and position relative to the table using encoders, infrared sensors, and a microcontroller. Multiple iterations of 3D prints have led to a more optimized design meant for fulfilling its objectives while remaining light and portable. New additions include a torsion spring working in tandem with a 70:1 gear motor in order to raise the firing chamber to a 45-degree angle for maximum distance. The torsion spring is critical in giving the motor the extra torque it needs to lift the firing chamber and keep it wherever it’s needed. (Shoot-o-Matic Poster)

Team: Drew Boyles (lead), Justin Gibbs, Scott Newcom, James Rollins, Shengwei Yang

Advisor: Dr. Ken Monson

During the summer months the majority of people use their air conditioning unit in the afternoon to cool down from the heat. During this time, electric companies charge up to three times more than they would charge during other times of the day. Conventional air conditioning systems use a pump, condenser, and fan which results in large power bills for the consumer. The goal of this project is to create an air conditioning system that costs 15% less to run than a widely used air conditioning unit of similar size.

During the summer months the majority of people use their air conditioning unit in the afternoon to cool down from the heat. During this time, electric companies charge up to three times more than they would charge during other times of the day. Conventional air conditioning systems use a pump, condenser, and fan which results in large power bills for the consumer. The goal of this project is to create an air conditioning system that costs 15% less to run than a widely used air conditioning unit of similar size.

To solve this problem, a chiller machine was designed to freeze a water-glycol solution into a slush when the cost of electricity is less expensive. This frozen slush will be used to air condition a space the next day when electricity prices are high. Since the condenser was used at night, only the fan and pump are used at this point, resulting in cost savings. Additionally, we will compare this to the costs of a window air conditioning unit of similar size. (Pumpable Ice Poster)

Team: Nicholas Lovell (lead), Ashley Rudd, Levis Wiggins, Nicholas Lovell, Garrett Smart

Advisor: Dr. Larry DeVries

In order to enhance the ambience at special events, our team has worked with Sapphire, a water fountain design company, to create a portable fountain capable to display patterns in a curtain of falling water. These patterns will be created by an array of individually actuated water valves. Custom designed nozzles and an understanding of Bernoulli’s, Plateau Rayleigh, and Venturi principles are implemented to achieve the desired effect. (Sapphire Poster)

In order to enhance the ambience at special events, our team has worked with Sapphire, a water fountain design company, to create a portable fountain capable to display patterns in a curtain of falling water. These patterns will be created by an array of individually actuated water valves. Custom designed nozzles and an understanding of Bernoulli’s, Plateau Rayleigh, and Venturi principles are implemented to achieve the desired effect. (Sapphire Poster)

Team: Luis Eduardo, Brock Emerson, Taylor Ogden, Jake Wilson (lead)

Advisors: Dr. Eric Pardyjak, James Harris

Vehicles parked in environments exposed to direct sunlight can reach dangerous temperatures when the outside temperature is between 80-100°F (27-38°C). Once vehicle cabin temperatures reach 110°F (43°C), the vehicle occupants are in danger of suffering from heat related illnesses. To lower the cabin temperature of the vehicle to a safe level for the vehicle occupants, our team designed a portable cooling unit that runs independently from the vehicle’s systems.

Vehicles parked in environments exposed to direct sunlight can reach dangerous temperatures when the outside temperature is between 80-100°F (27-38°C). Once vehicle cabin temperatures reach 110°F (43°C), the vehicle occupants are in danger of suffering from heat related illnesses. To lower the cabin temperature of the vehicle to a safe level for the vehicle occupants, our team designed a portable cooling unit that runs independently from the vehicle’s systems.

We researched the optimum temperature range for the vehicle cabin to prevent any bodily harm to the passengers. Then our team designed an independent and autonomous cooling system that is able to keep the cabin temperature of the vehicle within the acceptable temperature range. (Solar Car Cooler Poster)

Team: Andrew Feller, Beau Healey, Daniel Henshaw (lead), Matt Lalumia, Nick Spratt

Advisor: Dr. Meredith Metzger

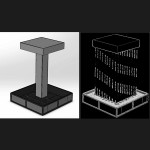

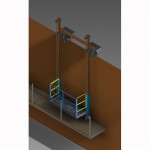

This team designed and fabricated a mobile scaffolding platform. This platform will be used to better facilitate the construction of large metal container tanks commonly found at refineries and mining facilities. It will be primarily used during the welding processes for constructing the container tanks. The platform will have both powered vertical and horizontal movement allowing the worker to focus completely on welding. This will speed up the welding process as well as increase weld quality. (Vert Buggy Elevator Poster)

This team designed and fabricated a mobile scaffolding platform. This platform will be used to better facilitate the construction of large metal container tanks commonly found at refineries and mining facilities. It will be primarily used during the welding processes for constructing the container tanks. The platform will have both powered vertical and horizontal movement allowing the worker to focus completely on welding. This will speed up the welding process as well as increase weld quality. (Vert Buggy Elevator Poster)

Team: Brad Bisignani, Tyler Neff, Nick Reay (lead)

Advisor: Dr. Larry DeVries

The project is to develop a wireless power transfer system and implement it with an unmanned aerial vehicle (UAV) such as a quadcopter, thereby supplying indefinite power to the UAV. We will demonstrate a quadcopter hovering several centimeters above the ground. (Wi-Fly Poster)

The project is to develop a wireless power transfer system and implement it with an unmanned aerial vehicle (UAV) such as a quadcopter, thereby supplying indefinite power to the UAV. We will demonstrate a quadcopter hovering several centimeters above the ground. (Wi-Fly Poster)

Team: Erik Andersen, Derek Driggs, Taylor Howell, Bryan Nay, Gregory Plaizier (lead)

Advisors: Drs. Kam Leang, Shad Roundy

FRESHMAN AND JUNIOR COMPETITIONS

Shuttle Run:

Shuttle Run:

ME EN 3210 Mechatronics COMPETITION

Saltair room

(1:00-3:30 p.m.)

Student-built robots will compete in head-to-head shuttle-run races in which they must traverse a playing field as fast as possible to push a button on the far wall and then get back to the starting line as fast as possible to push another button. Without any human intervention, and with minimal information about the playing field, the robots must traverse the course, and find and push the buttons (but not too hard, or they’ll be disqualified), all while the clock is ticking. Only the fastest robots will advance in this bracket-style competition.

PoKéPoNg: Gotta Catch ‘Em All!

PoKéPoNg: Gotta Catch ‘Em All!

ME EN 1010 freshman COMPETITION

West Ballroom

(12:00-3:00 p.m.)

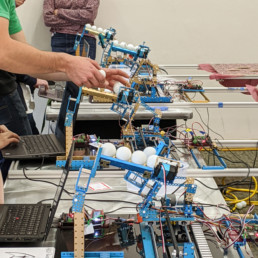

33 ME EN 1010 PoKéMoN trainer teams have entered the SAFARI ZONE! Each team has been given six Safari balls and two and a half minutes to catch up to six PoKéMoN in the Safari Zone. The best PoKéMoN trainer team will be the one who catches the most PoKéMoN in the shortest amount of time.

“GLOBAL SOLUTIONS” Water Pump Design:

“GLOBAL SOLUTIONS” Water Pump Design:

ME EN 1000 DESIGN COMPETITION

East Ballroom

(12:00-3:30 PM)

According to the World Health Organization, 1 in 10 people worldwide lack access to safe water. Providing improved drinking water sources for at-risk populations has been named by the United Nations as one of the top priorities of the new millennium. The preferred solution, especially in rural areas, has been to establish infrastructure for pumping water from protected wells. This has allowed people to abandon the practice of using polluted surface water, such as from lakes, rivers, ponds, and open irrigation canals, for drinking, thereby greatly improving health in the local area.

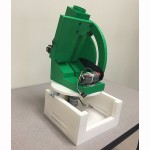

Students in ME EN 1000 were tasked with the design challenge of creating an inexpensive water pump as an “off-the-grid” solution to this problem. In the real-world application, water pumps are expected to use human-power from a bicycle. During the design competition, however, to ensure consistency and fairness, a small DC motor is used to power the pumps. Each team is provided with a MakeBlock starter kit and a budget for parts from a local hardware store. Teams design and build their systems using SolidWorks and hand tools, along with 3-D printers to fabricate custom parts. Teams are required to integrate practical course concepts into their designs. Teams are scored based on the mechanical efficiency of their pump and output produced, measured in terms of the volume of water pumped in two minutes. Winning teams will most definitely be the ones demonstrating the strong engineering skills.