Design Day - Fall 2019

Design Day is an opportunity to share our Senior Design Showcase with the public. Seniors work in groups with faculty to design and test projects.

Additionally, freshman and junior mechatronics’ students compete and showcase their skills.

Senior Design Projects

Nearly one in six couples around the world have trouble conceiving. There are ways to combat infertility on today’s market, but all of them are expensive and/or intrusive. The most common type of infertility is when the semen has low sperm count or low mobility. In this case, it is necessary to separate the sperm from white blood cells and proteins contained in semen. The separated sperm can then be used by medical personnel for direct insertion into the uterus. Today this process is only available at andrology clinics in metropolitan areas and is slow and unreliable as it is not automated and performed by a lab technician. People from rural areas don’t have access to similar technology. Thus, the project objective is to create a portable fully-automated device that is capable of sperm separation, and designed for use in rural areas. In order to prevent cross-contamination, the product utilizes a disposable replaceable cartridge which contains the spiral filter, tubing, and waste product. A sample cup is designed to be connected to the cartridge and its components. Since the flow rate is one of the major characteristics of the device, it is controlled through the user interface and microcontrollers. (Andrology Clinic in a Box poster)

Nearly one in six couples around the world have trouble conceiving. There are ways to combat infertility on today’s market, but all of them are expensive and/or intrusive. The most common type of infertility is when the semen has low sperm count or low mobility. In this case, it is necessary to separate the sperm from white blood cells and proteins contained in semen. The separated sperm can then be used by medical personnel for direct insertion into the uterus. Today this process is only available at andrology clinics in metropolitan areas and is slow and unreliable as it is not automated and performed by a lab technician. People from rural areas don’t have access to similar technology. Thus, the project objective is to create a portable fully-automated device that is capable of sperm separation, and designed for use in rural areas. In order to prevent cross-contamination, the product utilizes a disposable replaceable cartridge which contains the spiral filter, tubing, and waste product. A sample cup is designed to be connected to the cartridge and its components. Since the flow rate is one of the major characteristics of the device, it is controlled through the user interface and microcontrollers. (Andrology Clinic in a Box poster)

Team: Natalia Dominguez, Gabriel Milla, Daniel Mochizuki (lead), Travis Simpson

Faculty Advisors: Drs. Bruce Gale, Raheel Samuel

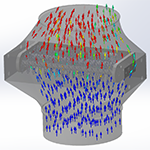

Many new homes today are built without gas stove connections. This denies the avid chef of the cooking performance gas stoves provide. For example, gas stoves immediately apply a large amount of heat to the cooking utensil when turned on as well as zero heat when turned off. Typical electric stoves can take several tens of seconds to heat up and cool down. Our goal is to design a stove that uses superheated air that can more closely match the performance of natural gas stoves. Our objectives are to achieve an air exit temperature of 900-1000 deg Celsius using 1.9-2.1 kW of energy, reach 60% of that temperature within two seconds and design a stove housing that is safe to use. (Convection Stove poster)

Many new homes today are built without gas stove connections. This denies the avid chef of the cooking performance gas stoves provide. For example, gas stoves immediately apply a large amount of heat to the cooking utensil when turned on as well as zero heat when turned off. Typical electric stoves can take several tens of seconds to heat up and cool down. Our goal is to design a stove that uses superheated air that can more closely match the performance of natural gas stoves. Our objectives are to achieve an air exit temperature of 900-1000 deg Celsius using 1.9-2.1 kW of energy, reach 60% of that temperature within two seconds and design a stove housing that is safe to use. (Convection Stove poster)

Team: Michael Campbell (lead), Ryan Duennebeil, Muhamad Ainuddin, Hector Merino, James Montgomery

Faculty Advisors: Drs. Tim Ameel, Shad Roundy

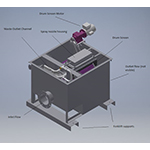

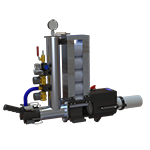

Our team is tasked with designing a compact and portable wastewater drum filter which acts as the second stage in the wastewater screening process at wastewater treatment facilities. The design must be able to filter out debris larger than 3mm from a maximum flow rate of 1 MGD (million gallons per day) of water. It must be small (roughly 27 cubic feet) and portable for small towns and rural area. The design must be able to operate 365 days per year with little or no maintenances required. (Drum Screen poster)

Our team is tasked with designing a compact and portable wastewater drum filter which acts as the second stage in the wastewater screening process at wastewater treatment facilities. The design must be able to filter out debris larger than 3mm from a maximum flow rate of 1 MGD (million gallons per day) of water. It must be small (roughly 27 cubic feet) and portable for small towns and rural area. The design must be able to operate 365 days per year with little or no maintenances required. (Drum Screen poster)

Team: Adnan Khan, Kyle Mays, Alik Nielsen, Jeremy Nguyen, Thomas Pembroke (lead)

Faculty Advisor: Dr. Bruce Gale

Wildfires play a significant role in ecosystems, but they can also cause loss of lives and damage to property. Studying the behavior of wildfire burn rates under varying conditions is an increasing necessity in order to understand how wildfires behave, mitigate destruction to property and risks to human lives. As part of a wildfire study, a tunnel capable of safely housing a controlled fire was created. Our project consists of creating a fan array that will attach to the existing tilting incendiary wind tunnel. The fan array is capable of simulating various realistic wind conditions such as wind speed, wind shear, and gusting. With the addition of the fan array, the incendiary wind tunnel will be used to study wildfire burn rates for varying slopes and wind condition combinations. This project has direct outcomes with use in outreach demonstrations, course labs, and graduate student research projects. (Fan Array Subsystem poster)

Wildfires play a significant role in ecosystems, but they can also cause loss of lives and damage to property. Studying the behavior of wildfire burn rates under varying conditions is an increasing necessity in order to understand how wildfires behave, mitigate destruction to property and risks to human lives. As part of a wildfire study, a tunnel capable of safely housing a controlled fire was created. Our project consists of creating a fan array that will attach to the existing tilting incendiary wind tunnel. The fan array is capable of simulating various realistic wind conditions such as wind speed, wind shear, and gusting. With the addition of the fan array, the incendiary wind tunnel will be used to study wildfire burn rates for varying slopes and wind condition combinations. This project has direct outcomes with use in outreach demonstrations, course labs, and graduate student research projects. (Fan Array Subsystem poster)

Team: Trevor Smith (lead), Walt Sorensen, Abdulrahman Yousuf, Abdullah Zamzami

Faculty Advisors: Drs. Eric Pardyjak, Rob Stoll

The Salt Lake City Mosquito Abatement District (SLCMAD) controls the population of mosquitoes to protect public health and increase the quality of life for residents of Salt Lake City. Most of the mosquito control efforts are conducted against juvenile mosquitoes, which live in water. Many of the prime mosquito habitats are freshwater marshes around the Great Salt Lake. Thick vegetation found in these wetlands makes it hard for liquid pesticides to reach the surface of the water, so SLCMAD uses granular formulations for many pesticide applications. Traditionally these pesticide applications to wetlands have been done on foot, by ATV or with a large tracked vehicle. These methods are labor intensive, cause heavy wear to equipment and can damage the environment.

The Salt Lake City Mosquito Abatement District (SLCMAD) controls the population of mosquitoes to protect public health and increase the quality of life for residents of Salt Lake City. Most of the mosquito control efforts are conducted against juvenile mosquitoes, which live in water. Many of the prime mosquito habitats are freshwater marshes around the Great Salt Lake. Thick vegetation found in these wetlands makes it hard for liquid pesticides to reach the surface of the water, so SLCMAD uses granular formulations for many pesticide applications. Traditionally these pesticide applications to wetlands have been done on foot, by ATV or with a large tracked vehicle. These methods are labor intensive, cause heavy wear to equipment and can damage the environment.

SLCMAD has recently started using highly technical unmanned aerial vehicles (UAVs) such as the DJI AGRAS MG-1S or Matrice 600 to make pesticide applications. These UAVs need custom fitting granular dispensing attachments. This senior design project has focused on the design and fabrication of a granular application system for an unmanned aerial vehicle. (Granular Application System poster)

Team: Bryson Bonner, Tanner Goates (lead), Bryce Johnson, Campbell McGavin, Rob Qualls, Brandon Tucker, Erik Urses

Faculty Advisor: Dr. M Metzger

Currently, drones used in surveying, inspecting, imaging, and other industrial and commercial applications are limited by their battery capacity and charging capabilities. We will mitigate this by enabling the drone to recharge its battery using the naturally occurring magnetic field generated by power lines. The drone will be able to grab onto power lines, and while secured to the line, use the principles of induction to induce a charge in an induction core installed on the drone. (Inductive Power Harvesting poster)

Currently, drones used in surveying, inspecting, imaging, and other industrial and commercial applications are limited by their battery capacity and charging capabilities. We will mitigate this by enabling the drone to recharge its battery using the naturally occurring magnetic field generated by power lines. The drone will be able to grab onto power lines, and while secured to the line, use the principles of induction to induce a charge in an induction core installed on the drone. (Inductive Power Harvesting poster)

Team: Nick Bierwolf, Klaus Griessmann (lead), Sean Harbertson, Ryan Kitchen, Dean Owen, Brage Platt

Faculty Advisor: Dr. Mark Minor

R2-D2 is a cultural icon, but the presence of operational droids in the community of Star Wars enthusiasts is limited. Our team addressed this gap by designing, developing and building a movie accurate, autonomous R2-D2. Our R2-D2 is a full-scale replica, which behaves similarly to the droid seen in the movies. Our prototype focuses on spatial awareness and pathfinding, as well as voice and obstacle recognition. The ideal context for use is for entertainment and outreach events, such as classes, camps, and STEM events. We hope to inspire people, both young and old, to get involved in technology and innovation. This may not save the world, but it will bring joy to many. (Industrial Automaton poster)

R2-D2 is a cultural icon, but the presence of operational droids in the community of Star Wars enthusiasts is limited. Our team addressed this gap by designing, developing and building a movie accurate, autonomous R2-D2. Our R2-D2 is a full-scale replica, which behaves similarly to the droid seen in the movies. Our prototype focuses on spatial awareness and pathfinding, as well as voice and obstacle recognition. The ideal context for use is for entertainment and outreach events, such as classes, camps, and STEM events. We hope to inspire people, both young and old, to get involved in technology and innovation. This may not save the world, but it will bring joy to many. (Industrial Automaton poster)

Team: Bobby Brisendine (lead), Adam Buchanan, Mike Neff, Rachel Phelps

Faculty Advisor: Dr. Kent Udell

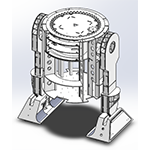

The MEK vertical axis wind turbine (VAWT) is a multi-year senior design project, started in the spring 2018 semester. The long-term goals of the project are to:

The MEK vertical axis wind turbine (VAWT) is a multi-year senior design project, started in the spring 2018 semester. The long-term goals of the project are to:

- Attempt to verify a numerical model based upon analytical methods for known properties of airfoil geometry and industry standard equations governing power harvesting from the wind;

- Provide a model for sustainable urban power generation in the Salt Lake Valley by first building a quarter scale VAWT that is capable of harvesting power from the wind gusts experienced in the area and converting it to electrical energy capable of powering small scale electronics;

- Build a full-scale VAWT, called the University of Utah Wind Turbine (UUWT) whose design is based upon that of the quarter scale MEK VAWT, and which is capable of generating 1kW of electrical power.

(MEK Vertical Axis Wind Turbine poster)

Team: Julia Alcox, Nils Mindnich, Daniel Moreno, Ian Pradhan (lead)

Faculty Advisor: Dr. M Metzger

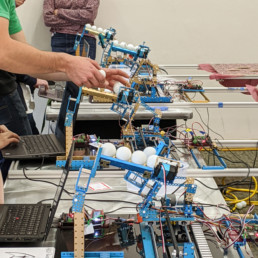

At many sporting events today, t-shirts and other objects are launched into the stands as a way to excite the crowd and help spectators have a positive experience at the event. While these commercial launchers do a great job of getting free items high into the stands, they generally have two key disadvantages. Either they are limited to one shot before requiring a reload or they are not portable by a single person.

At many sporting events today, t-shirts and other objects are launched into the stands as a way to excite the crowd and help spectators have a positive experience at the event. While these commercial launchers do a great job of getting free items high into the stands, they generally have two key disadvantages. Either they are limited to one shot before requiring a reload or they are not portable by a single person.

Our task was to remedy these issues by creating an air cannon that doesn’t have either of these disadvantages. The key design goals are that the cannon is able to shoot at least six t-shirts before requiring a reload, fire t-shirts at a rate of at least one t-shirt per second, launch t-shirts 200+ feet (high into the stands), be portable and operable by a single person, and be easy enough to operate that a person wearing a mascot suit can use it. (Portable Rapid-Fire T-Shirt Cannon poster)

Team: Chris Baert, Elliot Berg, Devin Dorius, Jon Duffin (lead), Thornton Garcia

Faculty Advisor: Dr. Owen Kingstedt

Swimming is a great activity for a number of reasons, such as, recreational or therapeutic exercises. Persons with limited use of their legs can sometimes find the transition between land and water difficult. Current methods for wheelchair bound people to enter a body of water independently is limited by their personal physique and dexterity or specialty equipment. A powered swim wheelchair is proposed to help those people easily and independently enter and exit any large body of water. Previous work has been done to provide a frame for such a vehicle. This project focuses on the engineering process for developing a drive system and adapting it for amphibious use on the aforementioned frame. (Powered Swim Wheelchair poster)

Swimming is a great activity for a number of reasons, such as, recreational or therapeutic exercises. Persons with limited use of their legs can sometimes find the transition between land and water difficult. Current methods for wheelchair bound people to enter a body of water independently is limited by their personal physique and dexterity or specialty equipment. A powered swim wheelchair is proposed to help those people easily and independently enter and exit any large body of water. Previous work has been done to provide a frame for such a vehicle. This project focuses on the engineering process for developing a drive system and adapting it for amphibious use on the aforementioned frame. (Powered Swim Wheelchair poster)

Team: Tanner Andrews, Gordon Kou (lead), Chunyang Yuan

Faculty Advisors: Drs. Andrew Merryweather, Jeffrey Rosenbluth

Many surgical procedures require the use of an electrocautery device, which uses an electric current to cut tissue or burn blood vessels to limit blood loss. However, electro-surgery produces a smoke plume, which limits the surgeon’s visibility and causes breathing problems for the surgical team. This issue is commonly addressed using a variety of vacuum-based fume exhaust systems. The primary challenge associated with smoke removal is that in order to be effective, the vacuum source must be placed in close proximity to the cauterization site without blocking the surgeon’s line of sight.

Many surgical procedures require the use of an electrocautery device, which uses an electric current to cut tissue or burn blood vessels to limit blood loss. However, electro-surgery produces a smoke plume, which limits the surgeon’s visibility and causes breathing problems for the surgical team. This issue is commonly addressed using a variety of vacuum-based fume exhaust systems. The primary challenge associated with smoke removal is that in order to be effective, the vacuum source must be placed in close proximity to the cauterization site without blocking the surgeon’s line of sight.

The project scope includes the development of an electrocautery pen with an integrated central suction core that removes a majority of the smoke produced during electro-surgery. By using an integrated configuration, the vacuum source can be placed at the cauterization site while minimizing visual obstruction of the surgeon. Other design considerations include an ergonomic design with duel functionality of cutting and coagulation. (Smokin’ Engineers poster)

Team: Paul DeMann (lead), Monica Downing, Hannah Roberts, Katherine Vega

Faculty Advisor: Dr. Dan Adams

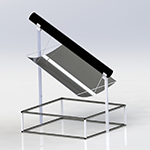

Our senior design goal is to build a portable parabolic reflector capable of tracking the sun’s location throughout the day. Using relationships that correlate the time of day to the sun’s location, we are able to focus the parabolic trough directly at the sun using a simple feedback control system.The parabolic reflector focuses radiation from the sun on a metal tube, heating its contents to high temperatures. This rotating parabolic reflector will later be attached to an ammonia refrigeration system designed by Professor Udell to generate sustainable air conditioning. (Solar Reflector and Support Frame poster)

Our senior design goal is to build a portable parabolic reflector capable of tracking the sun’s location throughout the day. Using relationships that correlate the time of day to the sun’s location, we are able to focus the parabolic trough directly at the sun using a simple feedback control system.The parabolic reflector focuses radiation from the sun on a metal tube, heating its contents to high temperatures. This rotating parabolic reflector will later be attached to an ammonia refrigeration system designed by Professor Udell to generate sustainable air conditioning. (Solar Reflector and Support Frame poster)

Team: Alex Boswell (lead), Irsyad Ismail, Hansl Park, Miles Quick, Landen Watts, Don Yang

Faculty Advisor: Dr. Kent Udell

The goal of our project is to create a heat exchanger (oil cooler) designed for trophy trucks that has the ability to be rebuilt. No current models on the market today have this ability. Oil in a trophy truck is pumped out of the engine and into a series of heat exchangers to cool the oil. Our heat exchanger will eliminate the need for multiple oil coolers, as the design we have created will yield the necessary 30 degree F temperature drop to cool the oil before it re-enters the engine. Our model design is a counter flow, shell and plate heat exchanger. Inside the shell will be two cores. Each core is made up of eight rectangular plates and four separator plates, allowing for four channels of oil flow per core, and five channels of coolant flow. The two cores will be connected with V-band clamps, which will allow each core to be removed separately in the event of a part or engine failure. The replaceability of the cores significantly reduces the cost of heat exchangers for trophy truck race teams. (Trophy Truck Heat Exchanger poster)

The goal of our project is to create a heat exchanger (oil cooler) designed for trophy trucks that has the ability to be rebuilt. No current models on the market today have this ability. Oil in a trophy truck is pumped out of the engine and into a series of heat exchangers to cool the oil. Our heat exchanger will eliminate the need for multiple oil coolers, as the design we have created will yield the necessary 30 degree F temperature drop to cool the oil before it re-enters the engine. Our model design is a counter flow, shell and plate heat exchanger. Inside the shell will be two cores. Each core is made up of eight rectangular plates and four separator plates, allowing for four channels of oil flow per core, and five channels of coolant flow. The two cores will be connected with V-band clamps, which will allow each core to be removed separately in the event of a part or engine failure. The replaceability of the cores significantly reduces the cost of heat exchangers for trophy truck race teams. (Trophy Truck Heat Exchanger poster)

Team: Garrett Fasig, Todd Salazar (lead), Gary Showalter, Mitchel Smith, Alain Villa

Faculty Advisors: Drs. Mathieu Francoeur, Sameer Rao

As municipal water networks expand, there needs to be an effective way to accurately measure pressure throughout the system. Existing methods only predict the pressure within the pipe by measuring it at the inlet and outlet or major junctions, leaving municipal water companies blind for what pressures are actually experienced in the middle of their pipe. To alleviate this, a small sensor needs to be placed within the pipe and must be capable of receiving power and transmitting data through the pipe wall without compromising the structural integrity of the pipe.

As municipal water networks expand, there needs to be an effective way to accurately measure pressure throughout the system. Existing methods only predict the pressure within the pipe by measuring it at the inlet and outlet or major junctions, leaving municipal water companies blind for what pressures are actually experienced in the middle of their pipe. To alleviate this, a small sensor needs to be placed within the pipe and must be capable of receiving power and transmitting data through the pipe wall without compromising the structural integrity of the pipe.

We propose to implement a method of power delivery and data transmission through a pipe using piezoelectric materials on opposing sides of the pipe. The external unit will be used to transmit power and receive data readings. The internal unit will receive the power and send sensor readings out. The addition of mid-pipeline sensors will allow for real-time updates to the pressures within the pipeline. (Ultrasonic Data & Power Transmission poster)

Team: Fumio Arima (lead), Tim Dostie, Matthew Dye, Junkang Gao, Vicente Sanhueza

Faculty Advisor: Dr. Shad Roundy