Design Day - Fall 2020

Design Day is an opportunity to share our Senior Design Showcase with the public. Seniors work in groups with faculty to design and test projects.

Senior Design Projects

With a sponsorship from L3Harris, we are developing a remotely operated device that can autonomously track in-flight aircraft with a high degree of accuracy using information from Automatic Dependent Surveillance Broadcast (ADS-B) signals. Direct line-of-sight between the transmitter and the receiver provides visual confirmation of the selected aircraft with the greatest security for data transfer. The project design is a 2-axis pedestal that rotates 360° about each axis. The pedestal is mounted on a tripod and powered by a gear train, with its two motors controlled by an onboard Arduino. An electronic rifle scope mounted on the pedestal is used for visual confirmation and measuring accuracy. The system is controlled remotely from a network computer using a Python-based Graphical User Interface (GUI), while an ADS-B receiver is integrated and used to collect data from passing aircraft. A LattePanda development board serves as the system CPU and interfaces between the ADS-B receiver, the computer, and the system. The user selects an aircraft from a list of tail numbers displayed on the GUI and the system begins tracking that aircraft.

With a sponsorship from L3Harris, we are developing a remotely operated device that can autonomously track in-flight aircraft with a high degree of accuracy using information from Automatic Dependent Surveillance Broadcast (ADS-B) signals. Direct line-of-sight between the transmitter and the receiver provides visual confirmation of the selected aircraft with the greatest security for data transfer. The project design is a 2-axis pedestal that rotates 360° about each axis. The pedestal is mounted on a tripod and powered by a gear train, with its two motors controlled by an onboard Arduino. An electronic rifle scope mounted on the pedestal is used for visual confirmation and measuring accuracy. The system is controlled remotely from a network computer using a Python-based Graphical User Interface (GUI), while an ADS-B receiver is integrated and used to collect data from passing aircraft. A LattePanda development board serves as the system CPU and interfaces between the ADS-B receiver, the computer, and the system. The user selects an aircraft from a list of tail numbers displayed on the GUI and the system begins tracking that aircraft.

Team: Freeman Allred (lead), Morgan Grant, Zach Lauritzen, Greg Liebelt, Alex Rooney, and Anthony Russo

Faculty Advisor: Dr. Stephen A. Mascaro

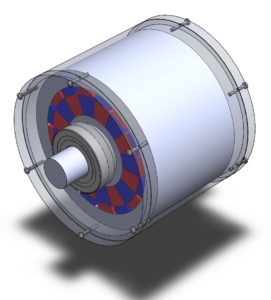

This is a device that is linked parallel with a motor to amplify the torque provided. It is taken a step further and runs off magnetic fields rather than current provided, which allow it to maintain a certain torque even when the power is shut off.

This is a device that is linked parallel with a motor to amplify the torque provided. It is taken a step further and runs off magnetic fields rather than current provided, which allow it to maintain a certain torque even when the power is shut off.

Team: Austin Beverley, Justin Bryant, John England, Zac Harston, Jacob Kennedy, and Brayden Newman (lead)

Faculty Advisor: Dr. Jake Abbott, Dr. Shad Roundy

In the pursuit of accessible and sustainable greens, this project seeks to contribute engineering knowledge to the DIY hydroponics community by creating an aeroponic system that is semi-autonomous, sustainable, open-source, designed for in-home use, and costs less than $600 to build.

Team: Sam Burbridge, Jacob Gonzalez (lead), Brooke Hadley, Alex Kratville, Hannah Lagerquist, Jon Matheson, Michaela Maxwell, Pat Zitting,

Faculty Advisor: Dr. Kam Leang

Team is creating an inerter to incorporate into building structures to mitigate vibration during seismic events. The inerter will raise the effective mass along a single axis, making it feel heavier when experiencing vibrations from an earthquake.

Team: Stephen Anderson, Brendan Oxborrow, David Ruggles, Ethan Eng-Tow, Juan Garcia, and Mitch Willes (lead)

Faculty Advisor: Dr. Pai Wang

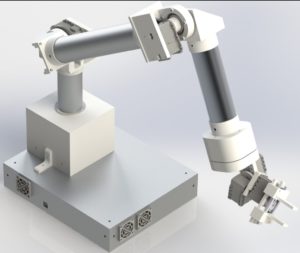

This 6-axis robotic arm will be used to load and unload test coupons for a hydraulic tensile testing machine. The hydraulic grips of the testing machine must apply substantial forces to the test coupon to properly constrain it. This creates a safety concern for the technician since they must place the coupon into the grips manually, the robot will automate the process to improve safety. The robot will also increase the accuracy of the tests since manual placement can introduce alignment errors. The robot will make this process more repeatable, thus improving the quality of the results.

This 6-axis robotic arm will be used to load and unload test coupons for a hydraulic tensile testing machine. The hydraulic grips of the testing machine must apply substantial forces to the test coupon to properly constrain it. This creates a safety concern for the technician since they must place the coupon into the grips manually, the robot will automate the process to improve safety. The robot will also increase the accuracy of the tests since manual placement can introduce alignment errors. The robot will make this process more repeatable, thus improving the quality of the results.

Team: Juan Altuna, Michaylo Chubak, John Goodman (lead), Rodrigo Leon, Bryce McCormick, Sergio Nunez,

Faculty Advisor: Dr. Jacob Dean Hochhalter

Grace is a seven-year-old who loves playing soccer; however, she cannot play without the assistance of a walker. Her current walker is marketed as an off-road walker, but it is difficult for her to use on the irregular terrain of a soccer field. Grace’s parents cannot modify her current walker and have been unable to find a walker for purchase that will not hinder her performance on the field. To improve Grace’s mobility off-road, our senior design team has designed and prototyped easily installable interchangeable wheel hubs for Grace’s walker that have terrain specific wheels for playing soccer and going to the beach. To ensure user safety, these hubs have a braking system and an anti-rollback device that can be engaged. The team has also prototyped additional walker add-ons including a lightweight walker seat.

Grace is a seven-year-old who loves playing soccer; however, she cannot play without the assistance of a walker. Her current walker is marketed as an off-road walker, but it is difficult for her to use on the irregular terrain of a soccer field. Grace’s parents cannot modify her current walker and have been unable to find a walker for purchase that will not hinder her performance on the field. To improve Grace’s mobility off-road, our senior design team has designed and prototyped easily installable interchangeable wheel hubs for Grace’s walker that have terrain specific wheels for playing soccer and going to the beach. To ensure user safety, these hubs have a braking system and an anti-rollback device that can be engaged. The team has also prototyped additional walker add-ons including a lightweight walker seat.

Team: Chad Anderson, Morgan Barron (lead), Reid Gardner, Jordy Osborne, Arthur Steur, Rulon Stitzer

Faculty Advisors: Dr. Andrew Merryweather

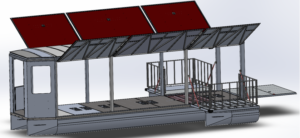

The Portable Accessible Docking System (PADS) is a large pontoon boat used by the University of Utah Healthcare and Engineering program to allow wheelchair patients to experience water sports such as boating, kayaking, fishing, and more. Currently, when the weather picks up the boat starts to rock. This poses a serious risk to patients in wheelchairs, some with minimal use of their limbs. The boat also is tight on space when all of the patients and crew are aboard. To combat these issues, our group was tasked with designing an outrigger to be placed at the back of the current PADS on both sides. Each outrigger will be composed of a pontoon and a deck attached to the current PADS. The goals of these outriggers are to help with the stability of the boat, provide extra space for use of patients and their care teams, and provide more buoyancy to the back of the boat which often sinks down during loading and unloading.

The Portable Accessible Docking System (PADS) is a large pontoon boat used by the University of Utah Healthcare and Engineering program to allow wheelchair patients to experience water sports such as boating, kayaking, fishing, and more. Currently, when the weather picks up the boat starts to rock. This poses a serious risk to patients in wheelchairs, some with minimal use of their limbs. The boat also is tight on space when all of the patients and crew are aboard. To combat these issues, our group was tasked with designing an outrigger to be placed at the back of the current PADS on both sides. Each outrigger will be composed of a pontoon and a deck attached to the current PADS. The goals of these outriggers are to help with the stability of the boat, provide extra space for use of patients and their care teams, and provide more buoyancy to the back of the boat which often sinks down during loading and unloading.

Team: Kevin Banick, Alex Campbell, Kyle Eichmeier, Landon Jensen, Kylar Segale, and Trevor Schwehr (lead)

Faculty Advisor: Dr. Andrew Merryweather

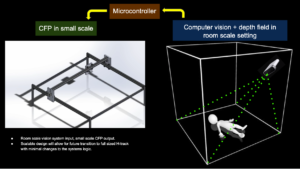

The purpose of the Smart H-Track system is to make life easier for healthcare workers and severely physically disabled patients. These patients might completely lack motor function below the neck. With such disabilities, moving from their bed to a wheelchair can pose an insurmountable challenge. So, they need health care workers to load them in and operate the H-track system manually. This process is laborious and time consuming. It can be physically taxing on healthcare workers, especially if the patient is heavy. The final goal is to make this process automated so that the patient can be loaded onto the H-track system and moved to a wheelchair or other location without the assistance of others. The system will perform the task autonomously. In order for this to be achieved, the patient will have a specially designed harness which is discrete in appearance and ergonomic in the lifting process (designed separately). The harness will have connection points which will be located by way of computer vision and depth field analysis. Once located, a connection device (designed separately) will be directed to that location. It will connect to the patient automatically, pick them up and move them to where they would like to go. This semester, we will be implementing our target localization program on a small physical prototype of the motor control system and frame.

The purpose of the Smart H-Track system is to make life easier for healthcare workers and severely physically disabled patients. These patients might completely lack motor function below the neck. With such disabilities, moving from their bed to a wheelchair can pose an insurmountable challenge. So, they need health care workers to load them in and operate the H-track system manually. This process is laborious and time consuming. It can be physically taxing on healthcare workers, especially if the patient is heavy. The final goal is to make this process automated so that the patient can be loaded onto the H-track system and moved to a wheelchair or other location without the assistance of others. The system will perform the task autonomously. In order for this to be achieved, the patient will have a specially designed harness which is discrete in appearance and ergonomic in the lifting process (designed separately). The harness will have connection points which will be located by way of computer vision and depth field analysis. Once located, a connection device (designed separately) will be directed to that location. It will connect to the patient automatically, pick them up and move them to where they would like to go. This semester, we will be implementing our target localization program on a small physical prototype of the motor control system and frame.

Team: Jacob Anderson (lead), Brandon Frieden, Mike McDonough, Mihir Pimpale, Alex Seeley, Dustin Sorenson,

Faculty Advisors: Dr. Andrew Merryweather

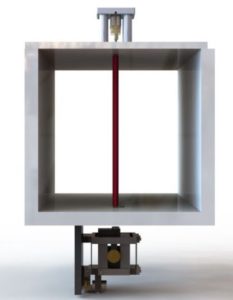

The thermal, fluid, and energy systems lab (TFES) is a fundamental course required by all upper-level mechanical engineering students. A particular lab in the course involves finding the lift and drag forces present on a symmetric airfoil. The existing apparatus for this lab presents key issues our team will be addressing: inaccurate and tedious changes of the angle of attack of the airfoil (students must change the angle of attack with a long Allen key while referencing a protractor) as well as excessive vibration of the airfoil during testing and resonant excitation of the magnetic coil in the Linear Variable Displacement Transducers (LVDT) sensor, which is responsible for recording the lift/drag forces. These issues lead to large fluctuations and uncertainty in the lift/drag force data obtained from the lab, which the students post-process to gain an understanding of airfoil characteristics and compare to published lift/drag force data of the symmetric NACA 0012 airfoil. Our team’s goals are to design an airfoil that accurately adjusts the angle of attack with an electric motor to within ±0.5 degrees and to reduce the fluctuations present in the lift/drag force data to within ±2% of the mean.

The thermal, fluid, and energy systems lab (TFES) is a fundamental course required by all upper-level mechanical engineering students. A particular lab in the course involves finding the lift and drag forces present on a symmetric airfoil. The existing apparatus for this lab presents key issues our team will be addressing: inaccurate and tedious changes of the angle of attack of the airfoil (students must change the angle of attack with a long Allen key while referencing a protractor) as well as excessive vibration of the airfoil during testing and resonant excitation of the magnetic coil in the Linear Variable Displacement Transducers (LVDT) sensor, which is responsible for recording the lift/drag forces. These issues lead to large fluctuations and uncertainty in the lift/drag force data obtained from the lab, which the students post-process to gain an understanding of airfoil characteristics and compare to published lift/drag force data of the symmetric NACA 0012 airfoil. Our team’s goals are to design an airfoil that accurately adjusts the angle of attack with an electric motor to within ±0.5 degrees and to reduce the fluctuations present in the lift/drag force data to within ±2% of the mean.

Team: David Dickerson (lead), Kaleb Killpack, Harrison Morford, Mathew Pawlak, Zachary Pickering, Jacob Zamora,

Faculty Advisors: Dr. M Metzger