Design Day - Spring 2016

Design Day is an opportunity to share our Senior Design Showcase with the public. Seniors work in groups with faculty to design and test projects.

Additionally, freshman and junior mechatronics’ students compete and showcase their skills.

Senior Design Projects

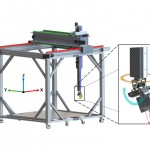

The 5-axis computer numerical control (CNC) scanning machine positions a sensor at any location within a 40″x40″x40″ scan volume and pointed perpendicular to the surface of an object being scanned. A laser displacement sensor is used to generate a comprehensive “point-cloud” of the object from which software can create a 3D computer model. That model will then be used to guide the path of ultra-sound and surface-impedance contact sensors that detect structural damage in the scanned object and integrate that information into the model. (5-Axis 3D Scanner poster)

The 5-axis computer numerical control (CNC) scanning machine positions a sensor at any location within a 40″x40″x40″ scan volume and pointed perpendicular to the surface of an object being scanned. A laser displacement sensor is used to generate a comprehensive “point-cloud” of the object from which software can create a 3D computer model. That model will then be used to guide the path of ultra-sound and surface-impedance contact sensors that detect structural damage in the scanned object and integrate that information into the model. (5-Axis 3D Scanner poster)

Team: Jacob Bartlett, Danny Buffington (lead), Erich Fabian, Thu Hoang, Tayson Holzer

Advisors: Dr. Kam Leang, Jon Davies

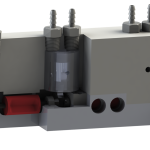

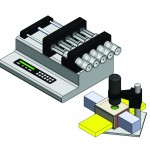

Wasatch Microfluidics needs to replace their microfluidic pump system. The 96 Channel Pump Team plans to develop a simplified multi-channel pump designed to address the customer’s needs. To overcome the deficiencies of the existing design, the designed device will include a simplified pump system, material that is compatible with the fluids to be pumped, and a storage location for the fluid. The pump will use the precious fluid instead of air as the driving fluid, thus increasing volumetric flow accuracy. The designed pump system will consist of 96 channels that will be able to aspirate or dispense simultaneously. Wasatch Microfluidics needs a single, compact, relatively inexpensive, non-contaminating, highly accurate pump system capable of pumping 96 samples simultaneously. (96 Channel Microfluidic Pump poster)

Wasatch Microfluidics needs to replace their microfluidic pump system. The 96 Channel Pump Team plans to develop a simplified multi-channel pump designed to address the customer’s needs. To overcome the deficiencies of the existing design, the designed device will include a simplified pump system, material that is compatible with the fluids to be pumped, and a storage location for the fluid. The pump will use the precious fluid instead of air as the driving fluid, thus increasing volumetric flow accuracy. The designed pump system will consist of 96 channels that will be able to aspirate or dispense simultaneously. Wasatch Microfluidics needs a single, compact, relatively inexpensive, non-contaminating, highly accurate pump system capable of pumping 96 samples simultaneously. (96 Channel Microfluidic Pump poster)

Team: Brian Butler, Rodolfo Garcia, Tanner Hatch (lead), Bryan Luke

Advisor: Dr. Bruce Gale

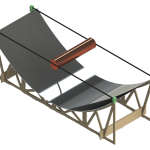

The Artificial Thermal Column Generator (ATCG) team studied the feasibility of utilizing Solar Updraft Tower technology (SUT) to alleviate high pollution levels in the Salt Lake Valley (SLV) during the winter months. This would be done by ventilating a portion of the total 2080 km^3 volume of SLV into the air above the inversion layer where it would be mixed with prevailing winds as in most other cities. SUTs work by heating ambient air in a large solar collector and using the buoyancy of that hot air to propel it upwards inside a large tower like column. Data acquired from SUTs as well as smelter stacks was analyzed during the design process. Due to the scale (up to 1.5 km high and 1700 km^2 in land space) and budget involved (an est. $1.6 billion), it would be impractical to build a full sized system, so the ATCG proved feasibility by using a FEA analysis and building a working scale model. ANSYS Fluent was used to recreate the environment and conditions present with the ATCG in order to model performance. This computer analysis will serve as the main source for modeling the system. (ATCG poster)

The Artificial Thermal Column Generator (ATCG) team studied the feasibility of utilizing Solar Updraft Tower technology (SUT) to alleviate high pollution levels in the Salt Lake Valley (SLV) during the winter months. This would be done by ventilating a portion of the total 2080 km^3 volume of SLV into the air above the inversion layer where it would be mixed with prevailing winds as in most other cities. SUTs work by heating ambient air in a large solar collector and using the buoyancy of that hot air to propel it upwards inside a large tower like column. Data acquired from SUTs as well as smelter stacks was analyzed during the design process. Due to the scale (up to 1.5 km high and 1700 km^2 in land space) and budget involved (an est. $1.6 billion), it would be impractical to build a full sized system, so the ATCG proved feasibility by using a FEA analysis and building a working scale model. ANSYS Fluent was used to recreate the environment and conditions present with the ATCG in order to model performance. This computer analysis will serve as the main source for modeling the system. (ATCG poster)

Team: Mohammed Alameri, Chandler Blessing, Hunter Loomis, Ben Stern (lead)

Advisor: Dr. Marc Calaf

The function of the Automated Stem Cell Separator(ASCS) is to remove the Stromal Vascular Fraction(SVF) from harvested adipose tissue. The ASCS is a completely mechanical device that creates a pressure drop to induce hydrodynamic cavitation which breaks down the adipose tissue structure allowing for the separation of the SVF. (Automated Stem Cell Separation poster)

The function of the Automated Stem Cell Separator(ASCS) is to remove the Stromal Vascular Fraction(SVF) from harvested adipose tissue. The ASCS is a completely mechanical device that creates a pressure drop to induce hydrodynamic cavitation which breaks down the adipose tissue structure allowing for the separation of the SVF. (Automated Stem Cell Separation poster)

Team: Anthony Berceau, Tyler Crouse, Justin Fawson (lead), Jesse Hanson, Zachary kelly, Agustus Schwab

Advisor: Dr. Himanshu Sant

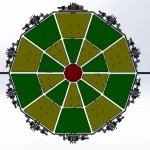

Steel shooting target designed for 0.22 caliber rounds. the design of the target is structured such that it resembles a classic dartboard. It is approximately 20″ in diameter. Swing arms are attached to the panels and will swing when hit with a round providing visual feedback. The target also incorporates sensors that will provide secondary visual feedback as well as keep score. (Ballistic Darts poster)

Steel shooting target designed for 0.22 caliber rounds. the design of the target is structured such that it resembles a classic dartboard. It is approximately 20″ in diameter. Swing arms are attached to the panels and will swing when hit with a round providing visual feedback. The target also incorporates sensors that will provide secondary visual feedback as well as keep score. (Ballistic Darts poster)

Team: Chancey Bailey, Scott Downard, Joe Leeman (lead), Jedediah Knight, Brian Martinez

Advisor: Dr. Mark Minor

The Cleanroom Robot Companion (CRC) is a robot that ensures the safety of lab occupants inside of the University of Utah’s Nanofab Cleanroom. This is accomplished by using the Google Tango tablet’s 3-D mapping abilities, which allow the robot to navigate its environment autonomously. Other features include video chatting, wireless communication, and the ability to follow humans. (Cleanroom Robot Companion poster)

The Cleanroom Robot Companion (CRC) is a robot that ensures the safety of lab occupants inside of the University of Utah’s Nanofab Cleanroom. This is accomplished by using the Google Tango tablet’s 3-D mapping abilities, which allow the robot to navigate its environment autonomously. Other features include video chatting, wireless communication, and the ability to follow humans. (Cleanroom Robot Companion poster)

Team: Travis Hainsworth, Zachary Lott, Joseph Melville (lead), Nicholas Posselli

Advisor: Dr. Ian Harvey

Over the past five years only one person in the Rocky Mountain area has built a rocket robust enough to withstand the monstrous thrust of the Cesaroni N10,000 rocket motor. This project is geared towards taming the beast with a rocket structure built completely from carbon fiber/epoxy composite material. Every structural component of the air frame has been engineered and manufactured specifically for the N10,000 by the Composite Rocket Team. Critical components have been to designed and confirmed to withstand five times the peak force imposed by the motor (motor peak thrust is 2600 lbs; weight of a small car). With the rocket’s extreme stiffness and lightweight characteristics it is anticipated to travel at speeds over Mach-one (speed of sound roughly 770 mph) and reach altitudes above 25,000 feet in the air (five miles high) with every foot of the flight captured with Go-Pro video footage. (Team KARBIN Composite Rocket poster)

Over the past five years only one person in the Rocky Mountain area has built a rocket robust enough to withstand the monstrous thrust of the Cesaroni N10,000 rocket motor. This project is geared towards taming the beast with a rocket structure built completely from carbon fiber/epoxy composite material. Every structural component of the air frame has been engineered and manufactured specifically for the N10,000 by the Composite Rocket Team. Critical components have been to designed and confirmed to withstand five times the peak force imposed by the motor (motor peak thrust is 2600 lbs; weight of a small car). With the rocket’s extreme stiffness and lightweight characteristics it is anticipated to travel at speeds over Mach-one (speed of sound roughly 770 mph) and reach altitudes above 25,000 feet in the air (five miles high) with every foot of the flight captured with Go-Pro video footage. (Team KARBIN Composite Rocket poster)

Team: Bryce Bigelow, Nathan Briggs, Kris Matheson (lead), Ivan Ortiz, Austin Smith, Ryan Wadge

Advisor: Dr. Michael Czabaj

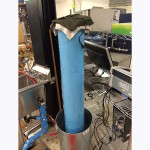

A patient that requires oxygen receives it via one of two ways: in a hospital through a high-pressure line or through a portable oxygen tank. At this time, neither of these two forms of oxygen delivery have sensors to monitor the patient’s breathing nor the oxygen flow levels while in operation. This project focuses on the design of an energy harvesting system to generate the power required to operate the sensors on the oxygen monitoring system. This eliminates the need for a separate battery pack or an outlet-powered source, which is not ideal because of additional required maintenance, cost of disposable parts, restrictions to mobility, limited battery life and reliability. The goal is to reduce the amount of oxygen used by creating a reliable, lightweight and mobile device that attaches to existing oxygen supply systems to improve oxygen delivery. (Energy Harvester for Pressure Line Monitoring poster)

A patient that requires oxygen receives it via one of two ways: in a hospital through a high-pressure line or through a portable oxygen tank. At this time, neither of these two forms of oxygen delivery have sensors to monitor the patient’s breathing nor the oxygen flow levels while in operation. This project focuses on the design of an energy harvesting system to generate the power required to operate the sensors on the oxygen monitoring system. This eliminates the need for a separate battery pack or an outlet-powered source, which is not ideal because of additional required maintenance, cost of disposable parts, restrictions to mobility, limited battery life and reliability. The goal is to reduce the amount of oxygen used by creating a reliable, lightweight and mobile device that attaches to existing oxygen supply systems to improve oxygen delivery. (Energy Harvester for Pressure Line Monitoring poster)

Team: Brandton Ferrin, Kevin Lund, Mykel Leffler, Jose Valadez, Tyler Unsworth

Advisor: Dr. Shad Roundy

Design, Test, Build, and Implement an Aerodynamic Package consisting of Front Wing, Rear Wing, and Underbody Tray for use on the 2016 Formula U Motorsports SAE race vehicle. (FSAE Aerodynamics poster)

Design, Test, Build, and Implement an Aerodynamic Package consisting of Front Wing, Rear Wing, and Underbody Tray for use on the 2016 Formula U Motorsports SAE race vehicle. (FSAE Aerodynamics poster)

Team: James Clark, Jesus Garcia, Carl Gatrell, John Muhs, Chase Sovereen (lead)

Advisor: Drs. Kuan Chen, Samuel Drake

The 2016 Chassis project was to reduce weight and optimize the design of the 2015 FSAE carbon fiber monocoque, as well as redesign the roll hoops and firewall. The monocoque was layed up at the DATC using high strength to weight carbon fiber laminate donated by Hexcel. The chassis will be used in the University of Utah FSAE race car that will be competing this summer. (FSAE Chassis poster)

The 2016 Chassis project was to reduce weight and optimize the design of the 2015 FSAE carbon fiber monocoque, as well as redesign the roll hoops and firewall. The monocoque was layed up at the DATC using high strength to weight carbon fiber laminate donated by Hexcel. The chassis will be used in the University of Utah FSAE race car that will be competing this summer. (FSAE Chassis poster)

Team: Kacey Abbott (lead), Jordan Alexander, Chris Carter, Charles Murphy, Jordan Waterman

Advisor: Drs. Brittany Coats, Samuel Drake

The Formula SAE is a student automotive design competition organized by SAE International. Each year, students from various universities meet to race newly designed cars based on specified rules and regulations. Each car is designed and manufactured by student teams aimed at creating the fastest, most powerful car. While other areas of the car are worked on by various specialized student teams, the University of Utah’s FSAE Engine Team has focused on the enhancement of the engine’s power directly while decreasing the overall weight of the drive train. To accomplish this task successfully, an analysis of the current engine is performed. Hypothesized solutions are then modeled and tested for actual engine performance gains. (FSAE Engine poster)

The Formula SAE is a student automotive design competition organized by SAE International. Each year, students from various universities meet to race newly designed cars based on specified rules and regulations. Each car is designed and manufactured by student teams aimed at creating the fastest, most powerful car. While other areas of the car are worked on by various specialized student teams, the University of Utah’s FSAE Engine Team has focused on the enhancement of the engine’s power directly while decreasing the overall weight of the drive train. To accomplish this task successfully, an analysis of the current engine is performed. Hypothesized solutions are then modeled and tested for actual engine performance gains. (FSAE Engine poster)

Team: Parker Brook, Reg Hamilton, Kade Heales, Matt Koplin, Carter Oman, James Orkin (lead)

Advisor: Dr. Drake

The FSAE Suspension team focused on four areas of design: suspension geometry, suspension compliance, steering, and manufacturability/visual appeal. Among other specifications, the team optimized the vehicle’s roll center, camber curve, caster, and wheel travel characteristics. The most important part of designing suspension for the FSAE car is keeping the wheels in contact with the road at all times. This includes suspension behavior during extreme conditions such as high speed cornering, braking, and acceleration. Optimization of these specifications allows the driver to focus on driving fast and to be confident in his ability to control the vehicle. (FSAE Suspension poster)

The FSAE Suspension team focused on four areas of design: suspension geometry, suspension compliance, steering, and manufacturability/visual appeal. Among other specifications, the team optimized the vehicle’s roll center, camber curve, caster, and wheel travel characteristics. The most important part of designing suspension for the FSAE car is keeping the wheels in contact with the road at all times. This includes suspension behavior during extreme conditions such as high speed cornering, braking, and acceleration. Optimization of these specifications allows the driver to focus on driving fast and to be confident in his ability to control the vehicle. (FSAE Suspension poster)

Team: Nick Butler, Grayden Elegante, Andre Romero, Spence Tan, Joel Williams (lead)

Advisors: Drs. Samuel Drake, Sanford Meek

The HapticPro, a three fingered haptic interface, is designed to be used as part of a haptic control system including a Quanser HD² and a three fingered robotic hand, such as the RightHand Robotics ReFlex TakkTile. The Quanser is a high-fidelity haptic interface that features a removable stylus that may be replaced with the HapticPro, giving full control of an underactuated robotic hand, while making use of sensors on fingers of the robotic hand to give haptic feedback to the users fingers and palm. This device can bring life to robotics in unmannable environments, such as space, underwater, and micro/macro scale work spaces, by making a robotic hand feel as if it were the users own hand. (HapticPro/ Three Fingered Haptic Interface poster)

The HapticPro, a three fingered haptic interface, is designed to be used as part of a haptic control system including a Quanser HD² and a three fingered robotic hand, such as the RightHand Robotics ReFlex TakkTile. The Quanser is a high-fidelity haptic interface that features a removable stylus that may be replaced with the HapticPro, giving full control of an underactuated robotic hand, while making use of sensors on fingers of the robotic hand to give haptic feedback to the users fingers and palm. This device can bring life to robotics in unmannable environments, such as space, underwater, and micro/macro scale work spaces, by making a robotic hand feel as if it were the users own hand. (HapticPro/ Three Fingered Haptic Interface poster)

Team: Connor Airmet (lead), Todd Bowles, Felix Desiena, John Oakley, Mike Kraszewski

Advisors: Dr. Jake Abbott, Nick Traeden

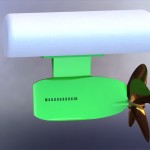

The HydroGEN is a portable hydroelectric generator that may be used in multi-day back country applications. It is designed to charge small electronics powered through a USB style plug. The HydroGEN produces power when placed in water flowing quickly enough to spin the small propeller. The power produced by the propeller is stored in internal batteries. Once the batteries are full, the HydroGEN is removed from the water source, and electronics may then be plugged into the USB ports to charge. (HydroGEN poster)

The HydroGEN is a portable hydroelectric generator that may be used in multi-day back country applications. It is designed to charge small electronics powered through a USB style plug. The HydroGEN produces power when placed in water flowing quickly enough to spin the small propeller. The power produced by the propeller is stored in internal batteries. Once the batteries are full, the HydroGEN is removed from the water source, and electronics may then be plugged into the USB ports to charge. (HydroGEN poster)

Team: Brian Childree, Nicholas Crawford (lead), Michael Turley

Advisor: Dr. Dan Adams

For many quadriplegics and paraplegics bedsores, also known as pressure sores are a serious threat to overall health and quality of life. Bedsores are the breakdown of skin and underlying tissue due to prolonged pressure on a concentrated point. Bedsores are most often developed around Ischial and hip bones. In current hospital settings solutions to mitigating the development of bed sores are limited to specialty beds that alternate inflatable sections to increase surface area and reduce overall pressure experienced by the individual. For those in wheel chairs there are some fairly effectively bedsore mitigation devices, however, they are limited to a sit-in cushion design and are extremely costly. The inflatable shorts team goal is to develop a wearable pair of shorts that will mitigate the development of bedsores wherever the patient is sitting. (Inflatable Shorts poster)

For many quadriplegics and paraplegics bedsores, also known as pressure sores are a serious threat to overall health and quality of life. Bedsores are the breakdown of skin and underlying tissue due to prolonged pressure on a concentrated point. Bedsores are most often developed around Ischial and hip bones. In current hospital settings solutions to mitigating the development of bed sores are limited to specialty beds that alternate inflatable sections to increase surface area and reduce overall pressure experienced by the individual. For those in wheel chairs there are some fairly effectively bedsore mitigation devices, however, they are limited to a sit-in cushion design and are extremely costly. The inflatable shorts team goal is to develop a wearable pair of shorts that will mitigate the development of bedsores wherever the patient is sitting. (Inflatable Shorts poster)

Team: Sean Jones, Shem Lemmon, Grant Mendenhall, Michael Pfeil, Alex Zvirzdin (lead)

Advisor: Dr. Himanshu Sant

While most schools have the resources available to teach microfabrication processes and techniques, many lack actual microscale devices for physical demonstrations since they are often difficult or expensive to create. These devices are often called lab-on-a-chip (LOC) since they scale laboratory-sized functions into the compact form of a chip. Physical fluidic phenomena such as capillary action, mixing, diffusion, droplet formation, and several others behave differently when scaled down to the microlevel from what we would intuitively expect in our macroworld. It is important for students to have an intuitive understanding of the physical laws which are dominant on the microscale before they are able to design for real-world applications. Our project was to fabricate LOC devices for the purpose of being educational tools which each demonstrates a physical phenomenon while still being affordable. Teachers could use these devices and their corresponding lesson plans as physical hands-on demonstrations in their curriculum. (Microfluidics Scaling Engineering poster)

While most schools have the resources available to teach microfabrication processes and techniques, many lack actual microscale devices for physical demonstrations since they are often difficult or expensive to create. These devices are often called lab-on-a-chip (LOC) since they scale laboratory-sized functions into the compact form of a chip. Physical fluidic phenomena such as capillary action, mixing, diffusion, droplet formation, and several others behave differently when scaled down to the microlevel from what we would intuitively expect in our macroworld. It is important for students to have an intuitive understanding of the physical laws which are dominant on the microscale before they are able to design for real-world applications. Our project was to fabricate LOC devices for the purpose of being educational tools which each demonstrates a physical phenomenon while still being affordable. Teachers could use these devices and their corresponding lesson plans as physical hands-on demonstrations in their curriculum. (Microfluidics Scaling Engineering poster)

Team: Samuel Feinman, Erika Hancock, Christopher Stolinski, Bryan Tran (lead)

Advisor: Dr. Brian Baker

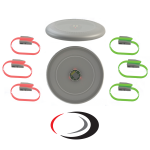

A system that allows the sport of ultimate Frisbee to be played at night through the use of an illuminated disc and illuminated wristbands. The different components of the system are connected through RFID communication. A mobile application is used to assign teams and start the game. The wristbands can be set to specific colors identifying the players’ team. The disc can change color to match the team in control when a player gains possession of the disc. After each point the disc indicates each team’s score. (Night Fury poster)

A system that allows the sport of ultimate Frisbee to be played at night through the use of an illuminated disc and illuminated wristbands. The different components of the system are connected through RFID communication. A mobile application is used to assign teams and start the game. The wristbands can be set to specific colors identifying the players’ team. The disc can change color to match the team in control when a player gains possession of the disc. After each point the disc indicates each team’s score. (Night Fury poster)

Team: Nick Arbanas, Alex Bailey, Carl Condas, JP Thomas

Advisors: Drs. Mark Minor, Ken Stevens

Quad+Guard is a quadcopter designed to assist first-responders in offshore aquatic rescues. Quad+Guard is equip with a remotely activated inflatable tube to provide flotation to drowning victims within moments of being spotted. Additionally, Quad+Guard provides 2-way audio with 1-way video to assist first-responders during rescue operations. (Quad+Guard poster)

Quad+Guard is a quadcopter designed to assist first-responders in offshore aquatic rescues. Quad+Guard is equip with a remotely activated inflatable tube to provide flotation to drowning victims within moments of being spotted. Additionally, Quad+Guard provides 2-way audio with 1-way video to assist first-responders during rescue operations. (Quad+Guard poster)

Team: Alec Bonham, Zach Dupaiz, Shane Reeve (lead), Brian Sheng, Adam Sperry, Tyler Trueax

Advisors: Daman Bareiss, Dr. Kam Leang

Many elderly and persons with disabilities struggle to get on and off the toilet by themselves forcing them to give up their independence and move to care facilities. There are currently passive devices such as toilet seat boosters and handrails that provide assistance with this task, but they are often inadequate. Several active lifting devices are available, but these devices are electric powered, which requires the user to run a power cord through the bathroom, because outlets are typically not located near the toilet. Another drawback is that these devices are too wide for many residential bathrooms therefore requiring renovation to install. The Rising Toilet Seat Team is addressing these problems by creating a hydraulic powered lift device. The device mounts in place of the toilet seat and uses the existing toilet water supply line for power. The water usage is small and the water is drained into the toilet tank so that it can be later used for flushing. No power outlet is required and the device is small enough to fit in the majority of bathrooms without any renovation. (Rising Toilet Seat poster)

Many elderly and persons with disabilities struggle to get on and off the toilet by themselves forcing them to give up their independence and move to care facilities. There are currently passive devices such as toilet seat boosters and handrails that provide assistance with this task, but they are often inadequate. Several active lifting devices are available, but these devices are electric powered, which requires the user to run a power cord through the bathroom, because outlets are typically not located near the toilet. Another drawback is that these devices are too wide for many residential bathrooms therefore requiring renovation to install. The Rising Toilet Seat Team is addressing these problems by creating a hydraulic powered lift device. The device mounts in place of the toilet seat and uses the existing toilet water supply line for power. The water usage is small and the water is drained into the toilet tank so that it can be later used for flushing. No power outlet is required and the device is small enough to fit in the majority of bathrooms without any renovation. (Rising Toilet Seat poster)

Team: Khoa Dinh, Jose Garcia, Cody Mitchell (lead), Brandon Wilstead

Advisors: Drs. Bala Ambati, Bruce Gale

3D Printing is no longer just for big business. Hobbyists are welcoming this rapid-prototyping technology into their homes, but the functionality of high-end printers is absent on basic machines. Even determining how much printing material is left can be a challenge. To help hobbyists use their machines more efficiently, the Robo Scale team is developing a device that determines the amount of plastic filament remaining on a spool of material. The scale reports the amount of filament left, and gives the user an approximation of how long it will take to deplete the roll. (Robo Scale poster)

3D Printing is no longer just for big business. Hobbyists are welcoming this rapid-prototyping technology into their homes, but the functionality of high-end printers is absent on basic machines. Even determining how much printing material is left can be a challenge. To help hobbyists use their machines more efficiently, the Robo Scale team is developing a device that determines the amount of plastic filament remaining on a spool of material. The scale reports the amount of filament left, and gives the user an approximation of how long it will take to deplete the roll. (Robo Scale poster)

Team: Keith Dockstader, Jeremie Jones (lead), Vu Lam, Milo Prisbrey, Spencer Smith

Advisor: Dr. Bob Roemer

![]() In neuroscience research, rodent researchers often use electrode implants in rodent brains to monitor neuron activity while specimens run through a maze. A common problem is that the cable gets caught on corners, or biases the experiment when a rodent notices cable slack and turns to chew on it. Our device aims to correct that problem by using sensors to “know” the direction the rodent is headed, and manage the cable by suspending it directly above the rodent. We’ve been asked by our customer, Blackrock Microsystems, to not introduce any unwanted noise or light into research mazes, and to also consider shipping and stocking concerns when designing the device. (Rodent Tracker poster)

In neuroscience research, rodent researchers often use electrode implants in rodent brains to monitor neuron activity while specimens run through a maze. A common problem is that the cable gets caught on corners, or biases the experiment when a rodent notices cable slack and turns to chew on it. Our device aims to correct that problem by using sensors to “know” the direction the rodent is headed, and manage the cable by suspending it directly above the rodent. We’ve been asked by our customer, Blackrock Microsystems, to not introduce any unwanted noise or light into research mazes, and to also consider shipping and stocking concerns when designing the device. (Rodent Tracker poster)

Team: Nicholas Brown, Joel Potter (lead), Nelson Radmall, Garrick Smith, William Yang

Advisor: Dr. Jake Abbott

Insects play an important role in the agriculture industry. Their actions can lead to the success or failure of a crop. How entomologists currently test insects’ preferences to different stimuli is limited and doesn’t allow for multiple stimuli concentrations during a test. Our team has worked to develop a new test chamber that can present multiple stimuli at varied concentrations to walking insects. The experiments ran in this new device have the insects’ activity automatically track to free up the researchers. With this device researchers will be able to gather useful information to help farmers have a successful crop. (Save the World’s Food Supply poster)

Insects play an important role in the agriculture industry. Their actions can lead to the success or failure of a crop. How entomologists currently test insects’ preferences to different stimuli is limited and doesn’t allow for multiple stimuli concentrations during a test. Our team has worked to develop a new test chamber that can present multiple stimuli at varied concentrations to walking insects. The experiments ran in this new device have the insects’ activity automatically track to free up the researchers. With this device researchers will be able to gather useful information to help farmers have a successful crop. (Save the World’s Food Supply poster)

Team: Tayler Bouck (lead), Elizabeth Durupt, Bryant Law

Advisor: Dr. Robert Roemer

Countless people, regardless of their location, are incapable of obtaining clean, safe water. Studies done by the World Health Organization (WHO) and UNICEF show that 783 million people do not have access to clean water. This is a human’s first priority for survival. Without clean water, diseases and illness kill upward of 8 million people per year. Because of this apparent need, our team proposes a way to make clean water for those in need. Out of the many options to clean water, our team chose to heat the water to a high enough temperature to eliminate any pathogens present. This process is known as pasteurization. However, by heating the water in a constant volume container, pressure will form, and the second use for our device is found. By extracting this pressurized water through coffee grounds, one is capable of making espresso. Here lies the main premise of our project: a device that is capable of producing clean water at a low cost but also able to brew an espresso for an outdoor enthusiast. (Solar Powered Espresso Machine poster)

Countless people, regardless of their location, are incapable of obtaining clean, safe water. Studies done by the World Health Organization (WHO) and UNICEF show that 783 million people do not have access to clean water. This is a human’s first priority for survival. Without clean water, diseases and illness kill upward of 8 million people per year. Because of this apparent need, our team proposes a way to make clean water for those in need. Out of the many options to clean water, our team chose to heat the water to a high enough temperature to eliminate any pathogens present. This process is known as pasteurization. However, by heating the water in a constant volume container, pressure will form, and the second use for our device is found. By extracting this pressurized water through coffee grounds, one is capable of making espresso. Here lies the main premise of our project: a device that is capable of producing clean water at a low cost but also able to brew an espresso for an outdoor enthusiast. (Solar Powered Espresso Machine poster)

Team: Ammar Almshab, Seth Butler, Vu Nguyen, Abdul Ozoya, William Richardson, Nelson Wetmore (lead)

Advisor: Dr. Kent Udell

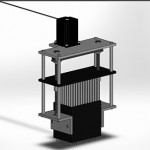

To design and develop a Thermal Energy Storage tank on a lab scale to use for laboratory testing. These tests will then be used to help develop more accurate computer modeling and to assist in studying the behavior of Thermal Energy Storage tanks over time. (Thermal Energy Storage poster)

To design and develop a Thermal Energy Storage tank on a lab scale to use for laboratory testing. These tests will then be used to help develop more accurate computer modeling and to assist in studying the behavior of Thermal Energy Storage tanks over time. (Thermal Energy Storage poster)

Team: Jon Darley, Jose Izurieta, Richard Peterson (lead), Nocholas Reeder, David Toth

Advisor: Dr. Amanda Smith

According to a study by the US Army, 1lb off of the foot is equivalent to between 4.7lb to 6.4lb off the back (JOHANSSON). While skis under 1000g have been made before, none of these skis meet the needs of our customers. We aim to break the norm by constructing an ultralight ski for use in backcountry terrain. Our ultralight skis will be targeted to the truly devoted skiers in search of the best untracked lines. They will weigh less than 1000g per ski while maintaining soft snow performance, stiffness, and durability. These skis will allow their user to travel farther with less effort and therefore ski more vertical feet. (Ultralight Backcountry Ski poster)

According to a study by the US Army, 1lb off of the foot is equivalent to between 4.7lb to 6.4lb off the back (JOHANSSON). While skis under 1000g have been made before, none of these skis meet the needs of our customers. We aim to break the norm by constructing an ultralight ski for use in backcountry terrain. Our ultralight skis will be targeted to the truly devoted skiers in search of the best untracked lines. They will weigh less than 1000g per ski while maintaining soft snow performance, stiffness, and durability. These skis will allow their user to travel farther with less effort and therefore ski more vertical feet. (Ultralight Backcountry Ski poster)

Team: Andrew Forhan, Ben Grandlic, Jacob Hopkins, Jeremiah Rogers, Lauren Starck (lead), Matt Visnovsky

Advisors: Drs. Marc Calaf, Kam Leang

The goal of this project is to create an interactive piece of gym equipment that will walk the user through a structured workout, ensure proper form during exercises, provide useful feedback, and build strength in a safe, timely manner. Because many gyms have already invested great amounts of money into their equipment, this project will focus on creating a set of hardware that can be mounted to existing exercise equipment. There will be two primary components to this hardware. (Upper Body Strength Building Device poster)

The goal of this project is to create an interactive piece of gym equipment that will walk the user through a structured workout, ensure proper form during exercises, provide useful feedback, and build strength in a safe, timely manner. Because many gyms have already invested great amounts of money into their equipment, this project will focus on creating a set of hardware that can be mounted to existing exercise equipment. There will be two primary components to this hardware. (Upper Body Strength Building Device poster)

Team: Hall Amornwithayawech, Jordan Gertino (lead), Joshua Lund, Blake Molis, Thad Walker

Advisor: Dr. Robert Roemer

FRESHMAN AND JUNIOR COMPETITIONS

RETURN TO MARS — BRAVO SITE:

RETURN TO MARS — BRAVO SITE:

ME EN 3210 Mechatronics COMPETITION

Saltair room

(1:00-3:30 p.m.)

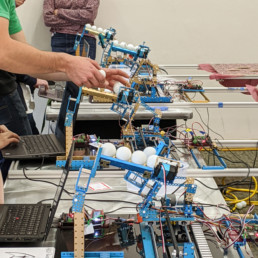

Utah engineers first attempted to Colonize Mars in 2013 to no avail, so in 2016 team alliances must design and build robots to return to Mars, attempt to build the infrastructure needed to accommodate human life, and gather geologic samples from the Martian surface for analysis. When their alliance arrives at Bravo site, though, building blocks are scattered across a rocky wasteland as shown in image, and they only have nine minutes to tele-operate their robots and prepare their colony.

The alliance must:

1) build structures for housing, communications, and food,

2) analyze rocks and gather magnetic samples,

3) gather rocks cluttering the environment,

4) store unused building materials, and

5) return the robots to their start positions.

Teams can make their colony even more desirable if they can move Minor’s Peak to the block storage area. The alliance that champions recolonization by earning the most points based upon their colonization will proudly wear the prized cloaks of their soon to be alma mater and bragging rights for years to come. Hopefully none of them live an unbalanced life and deplete their resources such that they lose the final and most important race against the ominous final exam and are forced to compete again in fall semester.

Star Wars — The Code Wars:

Star Wars — The Code Wars:

ME EN 1010 freshman COMPETITION

West Ballroom

(12:00-3:00 p.m.)

A Long Time Ago in a Galaxy Far, Far Away…..The ruthless First Order has constructed the Starkiller Base, a planet-sized superweapon capable of draining the energy of a star and focusing it into a beam that blasts through hyperspace to destroy entire planets. Led by Princess Leia, the noble Resistance has formed a desperate plan to eliminate the Starkiller Base by destroying its thermal oscillator, which should cause the base to explode when fully charged. While a squadron of X-wing fighters is busy engaging the enemy fighters in the sky above, a small group of Resistance fighters (codenamed unit 1010) has been deployed on the ground to disable the shield generators with ballistic weaponry. Intelligence reports show that precise hits on six locations will disable the shield generators so that the X-wings can swoop in to destroy the thermal oscillator. Program your droid well. Accuracy and time are of the essence. May The Force be with you!

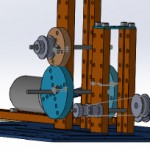

“GLOBAL SOLUTIONS” Water Pump Design:

“GLOBAL SOLUTIONS” Water Pump Design:

ME EN 1000 DESIGN COMPETITION

East Ballroom

(1:30-3:30 PM)

According to the World Health Organization, 1 in 10 people worldwide lack access to safe water. Providing improved drinking water sources for at-risk populations has been named by the United Nations as one of the top priorities of the new millennium. The preferred solution, especially in rural areas, has been to establish infrastructure for pumping water from protected wells. This has allowed people to abandon the practice of using polluted surface water, such as from lakes, rivers, ponds, and open irrigation canals, for drinking, thereby greatly improving health in the local area.

Students in ME EN 1000 were tasked with the design challenge of creating an inexpensive water pump as an “off-the-grid” solution to this problem. In the real-world application, water pumps are expected to use human-power from a bicycle. During the design competition, however, to ensure consistency and fairness, a small DC motor is used to power the pumps. Each team is provided with a MakeBlock starter kit and a budget for parts from a local hardware store. Teams design and build their systems using SolidWorks and hand tools, along with 3-D printers to fabricate custom parts. Teams are required to integrate practical course concepts into their designs. Teams are scored based on the mechanical efficiency of their pump and output produced, measured in terms of the volume of water pumped in two minutes. Winning teams will most definitely be the ones demonstrating strong engineering skills.