Design Day - Spring 2017

Design Day is an opportunity to share our Senior Design Showcase with the public. Seniors work in groups with faculty to design and test projects.

Additionally, freshman and junior mechatronics’ students compete and showcase their skills.

Senior Design Projects

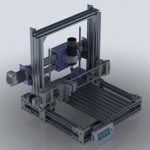

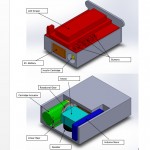

In manufacturing, computer numerical controlled (CNC) machining provides the ability to rapidly and precisely cut and shape raw material to create a wide variety of useful parts. Another manufacturing method, 3D printing, is becoming more frequently used, but this method can leave created objects with a rough surface finish and it can be difficult, if not impossible, to make overhangs, protrusions, or holes without manually adding support material to print on. This subtracts from ease of use and severely limits what kind of parts can be made by 3D printing. The idea of this project is to combine the benefits of both additive and subtractive CNC manufacturing into one machine to allow the freedom and ease of 3D printing with the precision of CNC machining. When combined, a limitless variety of objects may be created without the use of an extra support structure, without excessive material waste, and with a smoother finish.

In manufacturing, computer numerical controlled (CNC) machining provides the ability to rapidly and precisely cut and shape raw material to create a wide variety of useful parts. Another manufacturing method, 3D printing, is becoming more frequently used, but this method can leave created objects with a rough surface finish and it can be difficult, if not impossible, to make overhangs, protrusions, or holes without manually adding support material to print on. This subtracts from ease of use and severely limits what kind of parts can be made by 3D printing. The idea of this project is to combine the benefits of both additive and subtractive CNC manufacturing into one machine to allow the freedom and ease of 3D printing with the precision of CNC machining. When combined, a limitless variety of objects may be created without the use of an extra support structure, without excessive material waste, and with a smoother finish.

The purpose of this project is to determine how to secure 3D printed material to a surface strongly enough such that it may be machined in subsequent steps and not detach from its surface. Our group is focusing on a particular use for this technology in prosthetic development (e.g. arm, hand, or finger). With our machine, our goal is to shape a ‘skeleton’ substructure out of aluminum and 3D print thermoplastic ‘tissue/skin’ on top of it, where the plastic layer will subsequently undergo a machining process to clean up the surface and provide a more appealing aesthetic. (3-Axis CNC Machine & 3D Printer Poster)

Team: Shane Baca, Shawn O’Driscoll (lead), Devin Taylor, Brandon Wilkins, Jacob Zhao

Advisor: Dr. Sanford Meek

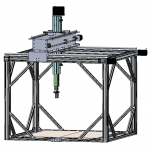

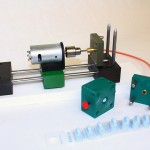

Sandia National Laboratories is in need of a machine that can perform non-destructive inspections on various objects. Non-destructive inspections utilize diverse sensors to inspect materials and objects for defects, cracks, and other deformities without damaging the item being examined. Currently, this process requires significant human labor and technical skill to manipulate and operate the sensors. This “5-Axis CNC Scanner” is an automated solution to this labor and skill intensive task. (5-Axis CNC Scanner Poster)

Sandia National Laboratories is in need of a machine that can perform non-destructive inspections on various objects. Non-destructive inspections utilize diverse sensors to inspect materials and objects for defects, cracks, and other deformities without damaging the item being examined. Currently, this process requires significant human labor and technical skill to manipulate and operate the sensors. This “5-Axis CNC Scanner” is an automated solution to this labor and skill intensive task. (5-Axis CNC Scanner Poster)

Team: Mallin Brough (lead), Brett Boyer, Devin Renshaw, Kevin Whipps

Advisor: Dr. Kam Leang

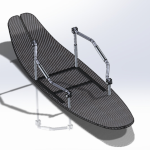

Adaptive recreation is a growing market worldwide. However, the current equipment does not meet the needs of the participants. Programs are generally using the same ski and seat, or ‘cage’ design. The design shortcomings include safety and ease of use. For example, the current cage is not adjustable for different-sized participants. If it is not properly sized for a given rider, one must switch that cage out for a completely new cage. This requires unnecessary time, effort, cost, and storage space for multiple cages.

Adaptive recreation is a growing market worldwide. However, the current equipment does not meet the needs of the participants. Programs are generally using the same ski and seat, or ‘cage’ design. The design shortcomings include safety and ease of use. For example, the current cage is not adjustable for different-sized participants. If it is not properly sized for a given rider, one must switch that cage out for a completely new cage. This requires unnecessary time, effort, cost, and storage space for multiple cages.

The objective of our team is to advance the technology employed in sit-down water skiing by designing and building a universal adaptive water ski. It will provide safety via enhanced side-to-side stability, adjustability via allowing for a single cage to be modified for different riders, and ease of use via allowing it to be stored, transported, and transferred in and out of water efficiently.

Team: Elliott Barth, Austin Frick, Jennifer Magee, Dallin Rees (lead)

Advisor: Dr. Andrew Merryweather

To maintain their health and current lifestyle, people with Type I Diabetes use an insulin pump to control and maintain their blood sugar throughout the day. Our team has been working on making an insulin pump that is less expensive than the current model, but just as safe and accurate at delivering insulin to the patient. We accomplished this by designing a kit assembly model that will be more affordable, customizable, and allow for individual part replacement. Patients will no longer need to replace the entire pump if one part fails. (Affordable Insulin Pump Poster)

To maintain their health and current lifestyle, people with Type I Diabetes use an insulin pump to control and maintain their blood sugar throughout the day. Our team has been working on making an insulin pump that is less expensive than the current model, but just as safe and accurate at delivering insulin to the patient. We accomplished this by designing a kit assembly model that will be more affordable, customizable, and allow for individual part replacement. Patients will no longer need to replace the entire pump if one part fails. (Affordable Insulin Pump Poster)

Team: Cherry Gregory, Young-Jun Jeon, Joshua Stubbs, McKayla Whitehead (lead)

Dr. Bruce Gale

AMPS is a ground-based, omni-directional robot designed to autonomously follow a commercially obtained multicopter drone while providing it with electrical power through a cable tether. In exchange for a moderate decrease in overall mobility, the attached drone can fly for more than 45 minutes, more than doubling its original flight time. Eventually, platforms like this could be used for inspection, videography, and surveying applications. (AMPS Poster)

AMPS is a ground-based, omni-directional robot designed to autonomously follow a commercially obtained multicopter drone while providing it with electrical power through a cable tether. In exchange for a moderate decrease in overall mobility, the attached drone can fly for more than 45 minutes, more than doubling its original flight time. Eventually, platforms like this could be used for inspection, videography, and surveying applications. (AMPS Poster)

Team: Jeppesen Feliciano, Matthew Givens (lead), Zach Jensen

Advisor: Dr. Kam Leang

The Automated Stem Cell Separator group developed a mechanical device for separating stem cell from human adipose (fat) cells so that the stem cells can then be used for medical treatment and reintroduced to the same patient. A mechanical approach was used to meet FDA regulations. Specifically, a fluid cavitation process, which creates small shockwaves resulting from a swift change in pressure within the device, was used to break apart the adipose tissue and detach the cells from the surrounding fat. Multiple designs of the device were fabricated and tested to determine an optimal design that could be incorporated into a full system that separates the stem cells for subsequent reintroduction into the patient. (Automated Stem Cell Separation Poster)

The Automated Stem Cell Separator group developed a mechanical device for separating stem cell from human adipose (fat) cells so that the stem cells can then be used for medical treatment and reintroduced to the same patient. A mechanical approach was used to meet FDA regulations. Specifically, a fluid cavitation process, which creates small shockwaves resulting from a swift change in pressure within the device, was used to break apart the adipose tissue and detach the cells from the surrounding fat. Multiple designs of the device were fabricated and tested to determine an optimal design that could be incorporated into a full system that separates the stem cells for subsequent reintroduction into the patient. (Automated Stem Cell Separation Poster)

Team: Travis Gowen, Joelle Hardy, Nelson Nieto, Brianna Potter, Megan Roach (lead)

Advisors: Drs. Bruce Gale, Himanshu Sant

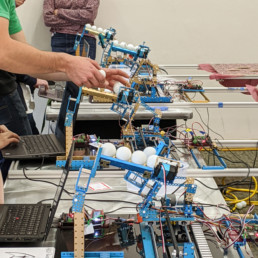

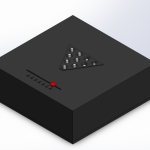

Visually impaired bowlers require the assistance of a spotter to give them feedback. The most important information a bowler needs is the number and location of pins that remain after a throw as well as the pocket that the ball struck. This information allows the bowler to know how they are performing as well as what they need to do to improve. The Blind Bowling Assistive Device will inform the user of what pins are remaining and ball impact location via a tactile display. This will increase the independence of blind bowlers and reduce the need for a spotter. (Blind Bowling Assistive Device Poster)

Visually impaired bowlers require the assistance of a spotter to give them feedback. The most important information a bowler needs is the number and location of pins that remain after a throw as well as the pocket that the ball struck. This information allows the bowler to know how they are performing as well as what they need to do to improve. The Blind Bowling Assistive Device will inform the user of what pins are remaining and ball impact location via a tactile display. This will increase the independence of blind bowlers and reduce the need for a spotter. (Blind Bowling Assistive Device Poster)

Team: Ashley Crawford (lead), Carl Herriott, Jamison Nielson, Von Williams

Dr. Mark Fehlberg

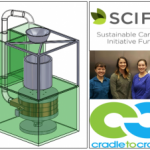

Our primary objective is to design and construct a sustainable coffee maker. Sustainability is measured through Cradle-to-Cradle (C2C) certification, which is a design philosophy emphasizing the life-cycle sustainability of a product. C2C evaluates products against five different categories: Material Health, Material Reutilization, Renewable Energy and Carbon Management, Water Stewardship, and Social Fairness. In order to meet gold or platinum certification, a few requirements include: using no banned materials, completing a nutrition management strategy, utilizing a minimum of 50 percent renewable energy sources, and ensuring that waste producing processes are minimized. Our model aims to accomplish this through a magnetically induced current design, where manually spun magnets generate at least half of the coffee maker’s energy source. (Cradle-to-Cradle Coffee Maker Poster)

Our primary objective is to design and construct a sustainable coffee maker. Sustainability is measured through Cradle-to-Cradle (C2C) certification, which is a design philosophy emphasizing the life-cycle sustainability of a product. C2C evaluates products against five different categories: Material Health, Material Reutilization, Renewable Energy and Carbon Management, Water Stewardship, and Social Fairness. In order to meet gold or platinum certification, a few requirements include: using no banned materials, completing a nutrition management strategy, utilizing a minimum of 50 percent renewable energy sources, and ensuring that waste producing processes are minimized. Our model aims to accomplish this through a magnetically induced current design, where manually spun magnets generate at least half of the coffee maker’s energy source. (Cradle-to-Cradle Coffee Maker Poster)

Team: Rumal Kaluarachchi, Sierra Krippner, Katie Talda, Marie VanderVliet (lead)

Advisor: Dr. Roseanne Warren

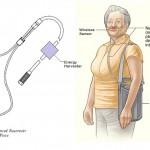

Many patients in hospitals use extra oxygen to assist with their breathing. Currently there is no sensing capability in the oxygen lines to determine if the patient is getting enough oxygen. A wireless pressure sensor could determine if the patient is still breathing and if the cannula (the piece that goes into the patient’s nostrils) is in place. In the case where the oxygen is supplied by an oxygen tank, a wireless flow sensor can detect if the oxygen has run out. These sensors and wireless communication require electrical power. Using batteries creates maintenance and reliability concerns. Because these lines are typically at high pressure (~55 psi), but the oxygen is delivered at low pressure (~0.5 psi), there is a potential source of untapped power that could be converted to electricity to run the sensors with no need to resort to batteries.

Many patients in hospitals use extra oxygen to assist with their breathing. Currently there is no sensing capability in the oxygen lines to determine if the patient is getting enough oxygen. A wireless pressure sensor could determine if the patient is still breathing and if the cannula (the piece that goes into the patient’s nostrils) is in place. In the case where the oxygen is supplied by an oxygen tank, a wireless flow sensor can detect if the oxygen has run out. These sensors and wireless communication require electrical power. Using batteries creates maintenance and reliability concerns. Because these lines are typically at high pressure (~55 psi), but the oxygen is delivered at low pressure (~0.5 psi), there is a potential source of untapped power that could be converted to electricity to run the sensors with no need to resort to batteries.

The goal of this project is to develop a power generator that utilizes high pressure oxygen at low flow rates (1-7 liters/minute) to generate 18-40 mW of electrical power that can be used to power the proposed wireless pressure and flow sensors. (Energy Harvesting from Hospital High Pressure Lines Poster)

Team: John Callaway, Hansel Halverson, Chris Kamerath, Lea Vanderlinden (lead), Lee Wilken

Dr. Shad Roundy

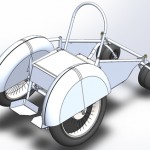

The objectives of the FSAE (Formula Society of Automotive Engineers) Chassis and Suspension Team is to develop a platform that conforms to the rules for racing in the SAE International’s Formula Student race series, is inexpensive, and can accommodate a variety of powertrains. The content of the FSAE rules booklet is too intensive to list here in detail, however, the goal of each safety measure is to keep team members from sustaining any injuries.

The objectives of the FSAE (Formula Society of Automotive Engineers) Chassis and Suspension Team is to develop a platform that conforms to the rules for racing in the SAE International’s Formula Student race series, is inexpensive, and can accommodate a variety of powertrains. The content of the FSAE rules booklet is too intensive to list here in detail, however, the goal of each safety measure is to keep team members from sustaining any injuries.

This year the team has selected an all-electric powertrain presenting a whole new section of rules that must be followed. The electric vehicle possesses large amounts of stored energy capable of causing serious injury to the driver and rendering the vehicle inoperable. The rules that apply to all powertrains is the driver compartment must be built to protect the driver if the vehicle were involved in a crash. (FSAE Chassis and Suspension Poster)

Team: Connor Barnes, Arman Dehlavi, Marc Ferguson (lead), Kenneth Finley, Valarie Isaac, Eric Koening, Keith Nelson, Jason Yu, Tyler Wilkerson

Advisor: Dr. Sam Drake

Our team is a subset of the FSAE (Formula Society of Automotive Engineers) club to build and race an electric SAE formula-style racecar. The Tractive Team is responsible for the electrical and dynamic mechanical systems of the car. Some of the parts included in the electrical section of our car are the electric motor, batteries and the low voltage systems. Some of the parts included in the dynamic mechanical system of our car include sprockets, gears, chain and the differential. To ensure safety and efficiency of our vehicle, SAE rules and guidelines are followed. (FSAE Tractive Poster)

Our team is a subset of the FSAE (Formula Society of Automotive Engineers) club to build and race an electric SAE formula-style racecar. The Tractive Team is responsible for the electrical and dynamic mechanical systems of the car. Some of the parts included in the electrical section of our car are the electric motor, batteries and the low voltage systems. Some of the parts included in the dynamic mechanical system of our car include sprockets, gears, chain and the differential. To ensure safety and efficiency of our vehicle, SAE rules and guidelines are followed. (FSAE Tractive Poster)

Team: Beau Blanchard, Kristoffer Edlund, Benett Lapray, David Pinnock (lead), Brandon Schmidt, Robert Underwood, David Van Ness, Jonathan Zubair

Advisors: Jon Davies, Dr. Sam Drake

A head mount for retinal surgery robots makes it possible for tele-manipulated robots to be attached to patient’s head during retinal surgery. This will mitigate or diminish the surgical challenges posed by the patient’s involuntary and voluntary movements, such as breathing and snoring. (Head Mount for Retinal Surgery Robots Poster)

A head mount for retinal surgery robots makes it possible for tele-manipulated robots to be attached to patient’s head during retinal surgery. This will mitigate or diminish the surgical challenges posed by the patient’s involuntary and voluntary movements, such as breathing and snoring. (Head Mount for Retinal Surgery Robots Poster)

Team: Gerardo Gonzalez, Renan Ichi (lead), Ryan Lam, Sarah Lebaron, Ryan Nielsen

Advisor: Dr. Jake Abbott

Every year the American Society of Mechanical Engineers (ASME) hosts the Human Powered Vehicle Competition (HPVC), inviting college students from all over to participate. The event includes a design review, speed test, and an endurance race. Vehicles are graded and scored based on their performance in each of these categories. Teams are encouraged to make vehicles that are easy to use, practical, versatile, and sustainable. This inspires designs useful to the general public rather than for the sole purpose of a competition.

Every year the American Society of Mechanical Engineers (ASME) hosts the Human Powered Vehicle Competition (HPVC), inviting college students from all over to participate. The event includes a design review, speed test, and an endurance race. Vehicles are graded and scored based on their performance in each of these categories. Teams are encouraged to make vehicles that are easy to use, practical, versatile, and sustainable. This inspires designs useful to the general public rather than for the sole purpose of a competition.

The 2016-2017 University of Utah HPV team will demonstrate proper engineering principles learned in a classroom setting by designing and fabricating a fast, efficient, sustainable, and practical human powered vehicle. Building off the previous designs the University of Utah has developed, the team this year is developing a two-wheeled, fully faired recumbent to compete in the ASME HPVC in Las Vegas, March 2017. (HPV Poster)

Team: Peter Jorgensen, Tanner Mouritsen, Travis Pellum, Vignesh Sivaramakrishnan (lead)

Advisor: Dr. Sanford Meek

In the United States there are an estimated 300,000 sports related concussions annually (Rowson,S. “Linear and Angular Head Acceleration Measurements in Collegiate Football”). The seriousness of mild traumatic brain injury (MTBI) is not well understood, but studies have suggested that it may have long lasting effects for athletes. Many groups, including the University of Utah, are working on improved helmet designs for various sports. However, many studies have shown that the underlying contributor to MTBI is a result of greater rotational acceleration of the head, which leads to increased shear stress in the brain tissue.

In the United States there are an estimated 300,000 sports related concussions annually (Rowson,S. “Linear and Angular Head Acceleration Measurements in Collegiate Football”). The seriousness of mild traumatic brain injury (MTBI) is not well understood, but studies have suggested that it may have long lasting effects for athletes. Many groups, including the University of Utah, are working on improved helmet designs for various sports. However, many studies have shown that the underlying contributor to MTBI is a result of greater rotational acceleration of the head, which leads to increased shear stress in the brain tissue.

To decrease the amount of rotational acceleration experienced by the head after impact, we propose the creation of a neck brace. This specific neck brace would utilize the properties of a non-newtonian fluid. When in normal play, the neck brace would be nothing more than a flexible fabric, so as not to interfere with the player’s ability to perform. However, as soon as impact occurred, the neck brace would stiffen; keeping the neck rigid and preventing the majority of the rotational acceleration experienced by the head. (Impact Induced Neck Brace Poster)

Team: Russ Brimley, McKenna Drysdale (lead), Bryan Grimm, KC Jensen, Raeleigh Jones

Advisor: Dr. Brittany Coates

Many hikers experience knee pain as a result of downhill hiking. The aim of this project is to design a device that will assist in alleviating this pain. Since pain is both subjective by individual and difficult to quantify, the design team’s proposed solution is to reduce the total reaction movement at the knee that occurs during downhill hiking. The proposed solution is the reCOiL, a knee brace that passively and effectively decreases the loading on the knee resulting from hiking descents. This carefully engineered reCOiL will be lightweight, adjustable, easy to use, and not restrict natural or functional motion. (Knee Exoskeleton for Assisted Descent Poster)

Many hikers experience knee pain as a result of downhill hiking. The aim of this project is to design a device that will assist in alleviating this pain. Since pain is both subjective by individual and difficult to quantify, the design team’s proposed solution is to reduce the total reaction movement at the knee that occurs during downhill hiking. The proposed solution is the reCOiL, a knee brace that passively and effectively decreases the loading on the knee resulting from hiking descents. This carefully engineered reCOiL will be lightweight, adjustable, easy to use, and not restrict natural or functional motion. (Knee Exoskeleton for Assisted Descent Poster)

Team: Colton Gines, Maggie Goertzen (lead), Mitch Metcalf, Adam Senekjian

Advisor: Dr. Ken Monson

The Omniboard is an electric skateboard that offers a unique recreational riding experience. To achieve omnidirectional movement the OmniBoard is equipped with an IMU (Inertial Measurement Unit) that communicates with a micro controller via an advanced PID loop. This loop takes the users reactions and movements, creates live data, and sends the information to three geared 12 volt DC motors equipped with encoders and omni wheels. The omni wheels are attached to a suspended sphere in the center of the board. The sphere is how omnidirectional movement can be achieved. (OmniBoard Poster)

The Omniboard is an electric skateboard that offers a unique recreational riding experience. To achieve omnidirectional movement the OmniBoard is equipped with an IMU (Inertial Measurement Unit) that communicates with a micro controller via an advanced PID loop. This loop takes the users reactions and movements, creates live data, and sends the information to three geared 12 volt DC motors equipped with encoders and omni wheels. The omni wheels are attached to a suspended sphere in the center of the board. The sphere is how omnidirectional movement can be achieved. (OmniBoard Poster)

Team: Connor Bevins, Cameron Cox, David Geddes (lead), Adam Magneson

Advisor: Dr. Stephen Mascaro

The PasCal is a quality assurance-testing device designed to perform pressure leak-down tests on a medical device known as a Luer cap. Luer caps disinfect the needle-less access sites on patient catheters and are used to prevent hospital-associated infections that occur in up to 1 in 20 admitted hospital patients. These infections are fatal in up to 25% of cases.

The PasCal is a quality assurance-testing device designed to perform pressure leak-down tests on a medical device known as a Luer cap. Luer caps disinfect the needle-less access sites on patient catheters and are used to prevent hospital-associated infections that occur in up to 1 in 20 admitted hospital patients. These infections are fatal in up to 25% of cases.

The PasCal test instrument is designed to perform pressure tests on these luer caps to validate the integrity of a foil seal that retains a disinfecting fluid within the cap. The device creates an access point in individual samples of finished product, pressurizes and then monitors internal pressure to determine the quality of the manufacturing process. The data the PasCal generates will be used to improve the quality of the Luer cap product through batch testing and statistical models. (PasCal – Medical Device Quality Test Instrument Poster)

Team: Scott Ferguson, Alex Pinegar (lead), Ricardo Rufino

Advisor: Dr. Robert Hitchcock

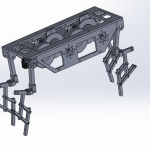

The Quadruped Robot is a passively stable four-legged robot meant to simulate the locomotion of four-legged animals. For this, each leg needs to be controlled independently from one-another. The task was to redesign previous versions of the robot to include four motors rather than two, one for each leg. Each motor has the capability to provide the power required to allow the robot to simulate walking and trotting.

The Quadruped Robot is a passively stable four-legged robot meant to simulate the locomotion of four-legged animals. For this, each leg needs to be controlled independently from one-another. The task was to redesign previous versions of the robot to include four motors rather than two, one for each leg. Each motor has the capability to provide the power required to allow the robot to simulate walking and trotting.

The robot chassis needed to be redesigned to incorporate the four motors along with the drive train components. These components include driveshafts, bearings, encoders, servos, gears, and belts. The challenge of this project was engineering the robot to remain light weight while designing for the needed torque and speed to attain the desired gaits. (Quadruped Robot Poster)

Team: Jessica Olsen-Rodriques, David Orr, David Templeton, Colton Thornley (lead)

Advisor: Dr. Sanford Meek

The current Texas Rollback trailer can easily load and unload low clearance vehicles using the tow vehicle as the driving mechanism but is limited to use in a straight-line and on flat dry surfaces. The primary goal and primary request of the customer is for an automated trailer using a remote control to increase the functionality of the existing trailer. To increase and maintain the existing functionality, are the following objectives:

The current Texas Rollback trailer can easily load and unload low clearance vehicles using the tow vehicle as the driving mechanism but is limited to use in a straight-line and on flat dry surfaces. The primary goal and primary request of the customer is for an automated trailer using a remote control to increase the functionality of the existing trailer. To increase and maintain the existing functionality, are the following objectives:

- Automate the loading and unloading of the trailer by remote

- Load capacity of the kit to be equivalent or greater than the current capacity of the trailer

- Maintain existing balance, ground clearance, and time required to load and unload

- Installation by the end user is simple requiring no welding

- Affordability of the product at $1000 or less

- Manual override of the kit allows trailer use in both automated and manual function

(RollBack Retrofit Kit Poster)

Team: Nic Andrews, Matt Burns, Iman Javaheri, Joel Roberts, Ellis Robinson (lead), Tyson Ronnow

Advisor: Dr. Ashley Spear

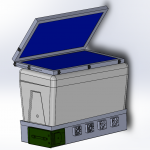

Relying on a limited quantity of ice to keep food cold on rafting trips or similar excursions away from electricity is difficult. The goal of this project is to harness the energy of the sun to grow ice in a cooler to extend cold food storage indefinitely. (Solar Powered Ice Box Poster)

Relying on a limited quantity of ice to keep food cold on rafting trips or similar excursions away from electricity is difficult. The goal of this project is to harness the energy of the sun to grow ice in a cooler to extend cold food storage indefinitely. (Solar Powered Ice Box Poster)

Team: Nate Curtis, Brandon Hammid, Jace Jones, John Larsen (lead), Max Mroz, Lei Tang

Advisor: Dr. Kent Udell

For millions of individuals who live with limited mobility and physical impairments, independence is often restricted because of the need to negotiate stairs and challenging terrains. Canes, walkers and wheelchairs are limited to level surfaces. This scarcity of available products leads to the need for caretaker assistance to provide support during these common activities of daily living. To overcome this problem and to address this urgent need, we propose a Stair Adaptable Walker (SAW).

For millions of individuals who live with limited mobility and physical impairments, independence is often restricted because of the need to negotiate stairs and challenging terrains. Canes, walkers and wheelchairs are limited to level surfaces. This scarcity of available products leads to the need for caretaker assistance to provide support during these common activities of daily living. To overcome this problem and to address this urgent need, we propose a Stair Adaptable Walker (SAW).

The SAW will improve a user’s mobility and independence by providing enhanced adaptive support during stair and slop ascent and descent with balance and postural stability. The secondary goal of the SAW is to match existing functionality of standard walkers on the market without adding significant cost and complexity. (SAW Poster)

Team: Chris Bolejack, Zake Liles, Andrew Ogden (lead), Matt Turner

Advisor: Dr. Sanford Meek

Over 319 million people worldwide live without access to safe drinking water. In an effort to address this, we designed a system that concentrates solar irradiation to boil water after filtration, producing clean and safe drinking water. The system requires no electrical power and has a minimalist design to keep costs low, while lasting for years of daily use. Ideal performance would be to produce 15 or more liters of clean water on an average sunny day in a climate similar to that of Sub-Saharan Africa, which is where the water crisis has the greatest impact. (Sustainable Water Purification Poster)

Over 319 million people worldwide live without access to safe drinking water. In an effort to address this, we designed a system that concentrates solar irradiation to boil water after filtration, producing clean and safe drinking water. The system requires no electrical power and has a minimalist design to keep costs low, while lasting for years of daily use. Ideal performance would be to produce 15 or more liters of clean water on an average sunny day in a climate similar to that of Sub-Saharan Africa, which is where the water crisis has the greatest impact. (Sustainable Water Purification Poster)

Team: Alan Barley, Devan Betts, Nick Iacopino, Taehoon Kim (lead), Dongwoon Shin

Advisor: Dr. Keunhan Park

This project involves the design and production of a working prototype for a submersible powered wheelchair. The intent is to use it to assist in transferring disabled individuals from the shore to a recreational water environment, such as a lake. The prototype would allow users to safely enter the lake environment independent of assistive individuals. The device would stay in the water until the individual is finished swimming. When the user is ready, he or she can reenter the chair and drive it back to shore.

This project involves the design and production of a working prototype for a submersible powered wheelchair. The intent is to use it to assist in transferring disabled individuals from the shore to a recreational water environment, such as a lake. The prototype would allow users to safely enter the lake environment independent of assistive individuals. The device would stay in the water until the individual is finished swimming. When the user is ready, he or she can reenter the chair and drive it back to shore.

Team: Niko Haukebo, Ramsey Hennis (lead), Keenan McCall, Casey Mervin

Advisors: Drs. Mark Fehlberg, Andrew Merryweather

U Brew is a fully autonomous all-grain brew system designed for innovative brewers. Through an advanced control system, human error is eliminated resulting in the production of consistent brews. One of the benefits is allowing users to perfect recipes knowing that any flavors come from ingredients rather than brewing techniques. (U Brew Poster)

U Brew is a fully autonomous all-grain brew system designed for innovative brewers. Through an advanced control system, human error is eliminated resulting in the production of consistent brews. One of the benefits is allowing users to perfect recipes knowing that any flavors come from ingredients rather than brewing techniques. (U Brew Poster)

Team: Jay Koch, John Lillquist, Jon Matthews (lead), Nolan Naftzger, Hank Schwab, Caleb Wray

Advisor: Dr. Mark Fehlberg

Having two parallel inflatable hulls, catarafts are very popular in conventional river rafting, and have numerous benefits over the more common single-hulled rafts. They inflate faster, move through the water quicker, and are more useable when water levels are low.

Having two parallel inflatable hulls, catarafts are very popular in conventional river rafting, and have numerous benefits over the more common single-hulled rafts. They inflate faster, move through the water quicker, and are more useable when water levels are low.

Our team inherited the original design from the first year’s team. This design included two inflatable hulls, an aluminum frame to span the hulls, and a backpack. The aluminum frame doubled as the external frame for the backpack. The whole system weighed 10.1 pounds.

The new objective is to eliminate the need to bring additional camping gear by incorporating them into the design. Most packrafters embark on multi-day trips. This implies that in addition to the rafting equipment the user must carry items such as a sleeping cot and camp chair. These items add weight and bulk to the load a person must carry. It is our goal to reduce the amount of equipment the packrafter is required to carry by incorporating these essentials directly into the packraft’s design. (Ultralight Hybrid Packrafting System Poster)

Team: Nathan Allott, Allison Coleman, Jared Gabaldon, Dustin Lee (lead), Alvaro Morales

Advisor: Dr. Dan Adams

Due to a series of wars in the 1970s and 80s there are currently an estimated five million landmines and thousands of tons of unexploded ordinances (UXOs) blanketing much of the undeveloped land in Cambodia. As the country develops demand for farmland increases, which necessitates clearing out UXOs. However, current demining efforts use old and dangerous methods requiring human labor, leading to injury and death. Remote-controlled robotic systems are preferred to help keep people out of harm’s way, but commercial demining robots are expensive, costing tens of thousands of dollars.

Due to a series of wars in the 1970s and 80s there are currently an estimated five million landmines and thousands of tons of unexploded ordinances (UXOs) blanketing much of the undeveloped land in Cambodia. As the country develops demand for farmland increases, which necessitates clearing out UXOs. However, current demining efforts use old and dangerous methods requiring human labor, leading to injury and death. Remote-controlled robotic systems are preferred to help keep people out of harm’s way, but commercial demining robots are expensive, costing tens of thousands of dollars.

An engineering team at Villanova University is currently developing an affordable remote-controlled demining robot, but the difficult terrain in Cambodia, combined with the requirement that the operators remain out of the blast radius, makes it extremely challenging to navigate the robot effectively.

They have asked our team to provide enhanced situational awareness for the operator of their robot by supplying a bird’s eye view from cameras on an aerial robot, programmed to autonomously follow the ground robot. Our specific focus for this project is on designing a control system that uses a video feed to track the ground robot and moves the aerial robot to keep it directly above the ground robot. (Vision-Based Aerial Robot for Demining Applications in Cambodia Poster)

Team: Katharin Jensen (lead), Tyler Larson, Jesse Lewis, Justin Ngo, Travis White

Advisor: Dr. Kam Leang