Design Day - Spring 2018

Design Day is an opportunity to share our Senior Design Showcase with the public. Seniors work in groups with faculty to design and test projects.

Additionally, freshman and junior mechatronics’ students compete and showcase their skills.

Senior Design Projects

Pre-Charged Pneumatic (PCP) air guns are popular air rifles among many users. PCP air guns function in a similar fashion to traditional firearms, only instead of using gunpowder to propel a projectile PCP air guns use compressed gases. As these gases escape when the air gun is fired a loud sound wave is created. Exposure to high levels of sound is undesirable as this can lead to hearing loss, poor shooting habits, and decreased interest in users. This project, the air gun baffle, is designed to reduce the sound emitted by an air gun when fired. The air gun baffle is a device that attaches to the end of the air gun that controls the rapid expansion of gases in order to reduce the sound wave created. Computational fluid dynamics (CFD) simulations were used to iterate the design and create the most effective air gun baffle. (Air Gun Baffle Poster)

Team: Brooke Bedford, Joshua Pratt, Cory Webb, Connor Webster (lead), Benjamin Weese

Advisor: Dr. Marc Calaf

Researchers at the U developed the AirU air-quality sensor package in hopes to bring a low-cost, air quality sensor to classrooms along the Wasatch Front. AirU sensor measures relevant levels of particle and carbon monoxide pollution. It also measures temperature, relative humidity, pressure, and GPS location. Originally 3D printed, the housing took almost 20 hours to print. Making it impractical for mass production. Our team’s goal is to integrate an efficient strategy for the production of low-cost air sensor housings. This project will play a major role in raising awareness of air pollution in the Salt Lake Valley as a whole. (AirU Sensor Housing)

Team: Daniel Carrick, Jack Drain, Maryam Mohseni, Jon Winegar (lead)

Advisor: Dr. Kerry Kelly

Most pets in the U.S. are overweight due to pet owners overfeeding cats and dogs. Our design prevents overfeeding from happening. Working with veterinarians to determine the correct amount of food, pet owners will be able to accurately dispense the correct amount of food in order to maintain a healthy diet for cats and dogs. The amount of food will be determined by the vet, and the owner will be able to enter that amount into the feeder. Along with dispensing the correct amount of food a scale is integrated into the design to help monitor and track the pet’s weight. This can be saved on an SD card and taken to the veterinarian to show the pet’s progress. To keep the pet hydrated a water dispenser is included. (Automated Pet Food Dispenser Poster)

Team: Austin Anderson, Matthew Gammon, Jason Newbold, Matt Whitehead (lead)

Advisor: Dr. Owen Kingstedt

Wireless x-ray imaging plates require a battery that is inserted into the back of the plate. The batteries are required to meet long reliability standards. A flexible, modular tester is needed to validate the life-cycle reliability of the latching mechanism using realistic insertion and removal of the battery to validate new designs and to allow for reproduction and field failures. (Battery Insertion and Wear Tester Poster)

Team: Trevor Hunt, Anup Khadka, Gage Taylor, Eric Tyler (lead)

Advisors: Drs. Sanford Meek, John Shen

Around 2.9 million Americans currently suffer from poor vision, and an estimated five million Americans will have low vision by the year 2030. The goal of Retinal Vein Cannulation Surgery is to place medicine into a 20 micron thick retinal layer. The medicine is placed through a syringe and can take up to 20 minutes to fully inject. If the medicine is properly placed, the procedure may be able to restore eyesight. Current surgery procedures do not have the precision to conduct this surgery effectively. To resolve this issue a high-precision robot has been created to assist the doctor’s in hitting the 20 micron target zone. This project is a mask-like device that will facilitate the mounting of the robot to a patient’s head during eye surgery. The mount will abide by current surgery procedures and maintain a sterile surgical field. (Eye Surgery Robot Mount Poster)

Team: Raphael Chanut, Austyn Ekker, Tashayla Openshaw, Keith Schendel, Cody Walker (lead)

Advisor: Dr. Jake Abbott

The Formula SAE design competition pits student teams against one another to see which team can design the best racing vehicle; each team competes in several static and dynamic events to determine the winner. For over 10 years, Formula U Racing has competed in the competition, however this is the first year that an ergonomics sub-team has been included. The ergonomics sub-team is specifically in charge of designing how drivers fit into and interface with the vehicle (such as seat, steering wheel, and pedals). To ensure their vehicle can be driven to its limits as intended, Formula U Racing has commissioned our team to design and manufacture a system that encompasses all driver interfaces of their race car in an ergonomically friendly fashion. (FSAE-Ergonomics Team Poster)

Team: Kylan Bringhurst, Paul Hawkins, Matt Lindsey (lead), Ethan Rigby, Daniel Webber, Matthew Zortman

Advisors: Drs. Sam Drake, Jon Davies

Like Tesla, the U is building an electric racecar. Our racecar will compete in the Formula SAE (Society of Automotive Engineers) competition in Lincoln, Nebraska. This is the second year that we will compete in the electric competition. In years past, a majority of teams were unable to complete the competition due to overheating batteries.

Our tractive team, which is a sub team of the entire team, is tasked with ensuring the batteries are safe. There are two major issues with electric cars: batteries get hot while accelerating and can explode with impact. We are aiming to keep our batteries temperatures below 50˚C in a worst-case scenario. The container will also withstand 40‘s laterally and longitudinally, and 20 ‘s vertically. This will be achieved through our design of a cooling system built into our designed protective encasement. (FSAE-Tractive Team Poster)

Team: Brandon Barker, Porchhay Ear, Luke Kandaris (lead), Matt Miller, Riley Welsh

Advisors: Drs. Sam Drake, Jon Davies

Mainstream 3D printing methods allow for the selection of only one source material to be printed at a time when creating parts. Our process increases the opportunity to print hybrid materials. New material composition of parts could allow for magnetic and/or electrical integration, as well as specific location-dependent control of physical properties. The scope of this project is to design a nozzle that can modify the input from two source materials and accurately create a gradient along a singular print bead on an existing platform. Our design differs from current printers in that we are actively mixing source material via a mixing rod inside of a mixing chamber. (Gradient Material Additive Manufacturing Poster)

Team: Mohammed Alnuman, Mitch Christensen (lead), Chase Ellis, Shardul Kamat

Advisor: Dr. Wenda Tan

The purpose of this senior project will be to design and fabricate a hot-wire foam cutter utilizing computer numerical control (CNC) for use in Dr. Metzger’s Turbulence and Renewable Energy Laboratory. She and her team specialize in the research and manufacturing of vertical axis wind turbines and unmanned aerial vehicles. Our program allows a standard STL file input and generates a method in order cut the final shape. It features three degrees of freedom and Matlab/Arduino integration. While hot-wire foam cutters exist, the benefit of this design will be the ability to customize shapes of high density foam for production and analysis, furthering innovation in the lab’s fields of study. (Hot Wire Foam CNC Cutter Poster)

Team: John Erickson, James Garriga, Ryan Johnson (lead), Sean Llewelyn

Advisor: Dr. Meredith Metzger

The Bioinspired Science and Engineering Laboratory utilizes a method known as freeze casting in order to cast porous ceramic materials that mimic biological structures. The freeze casting process utilized here consists of a cylindrical mold, approximately one inch in diameter and two inches in height, a ceramic slurry, a liquid nitrogen bath, and a copper rod which connects the mold to the liquid nitrogen bath. The liquid nitrogen bath and connecting copper rod facilitate heat transfer from the ceramic slurry to the liquid nitrogen bath. As heat is removed, the ceramic slurry freezes unidirectionally from the bottom of the mold to the top. In an effort to support future research efforts aimed at manipulating the mechanical properties of materials casted in this process, this design team has designed a robot which achieves two things. 1) Identifies the location of the ice front and 2) Positions a mechanical platform relative to the location of the freeze front. This will provide the Bioinspired Science and Engineering Lab with a tool that allows them to study the dynamics of freeze casting and to implement new procedures for innovating bioinspired mechanical structures. (Ice Tracking Robot Poster)

Team: Brandon Bethers, Haodan Chen, Kaden Plewe (lead), Connor Weems

Advisor: Dr. Steven Naleway

The goal of our project is to construct and operate a wind tunnel that is capable of safely modeling forest fires. This tunnel will be capable of modeling variable slopes, different fuel types and distributions, various wind speeds, and will also be mobile to allow for demonstrations. This incendiary wind tunnel will allow us to research the spread of fire and smoke while also giving us the ability to visually inspect the results. This is a multi-year project; our scope is the design and assembly of the wind tunnel and its mobility system, while future teams will design fan and sensing systems for the tunnel. (Incendiary Wind Tunnel Poster)

Team: Robert Lee, Ian McClane (lead), Jonnie Merrill, Jarrett Smith, Damien Whitehead

Advisors: Drs. Eric Pardyjak, Rob Stoll

For the outdoor enthusiast looking to get out and explore lakes, rivers or any body of water and experience the speed and adrenaline found in action water sports such as jet skiing and wake boarding, LakeSurfer is what you have been looking for! It combines the thrill of wake boarding with the ability to explore found in paddle boarding. By combining a 4-stroke gas engine with a custom built and manufactured board, it is capable of reaching speeds of 15 mph. At an estimated price of $3,000 LakeSurfer brings affordability and accessibility to the water sports and power sports market at the same time. Being light and maneuverable makes it an option for beginners as well as experienced riders. Come take a look and see the LakeSurfer in action! (LakeSurfer Poster)

Team: J.D. Baranowski, Mike Doney (lead), Mike Giere, Justin Tomlinson, Alex Willie

Advisor: Dr. Ken Monson

The future of vision restoration may be closer than we think with the development of visual neuroprosthetics. Visual neuroprosthetics convert images into electrical impulses sent directly to the brain through implanted microelectrode arrays. In order to generate the highest resolution possible, the microelectrode arrays must be implanted in the primary visual cortex (V1). Access to this region of the brain is challenging due to the limited space between the brain’s hemispheres.

The objective of our project was to design and manufacture a unique high-speed insertion tool capable of inserting a 4×4 mm microelectrode array within a 1 cm space. In collaboration with Blackrock Microsystems, we developed an electromagnetic system capable of perpendicular implantation within a limited space. The electromagnetic system rapidly accelerates a magnetic cylinder to > 2 m/s, and transfers momentum to the array. The tool resets after each insertion to minimize the time required to implant multiple arrays. The small footprint and high performance of the insertion tool allows access to hard to reach regions of the brain, and increases the opportunity for successful vision restoration using neuroprosthetics. (Lateral Insertion Tool for Cortical Microelectrode Arrays Poster)

Team: Jadesola Aderibigbe (lead), Phil Beasley, Jayden Plumb, Emily Radivoyevich, Keith Warner

Advisor: Dr. Brittany Coats

Our project was chosen to address an all-too-common problem: temporary power and hot water for people suffering from a traumatic, natural disaster. We have derived a prototype that will utilize solar rays to generate hot water and power for these traumatized individuals. Our creation is modular, so it is capable of creating lots of hot water and power as a superposed system. (Portable Solar Power System Poster)

Team: Dallan Child, Praja Katel, Spencer Landeen (lead), Nicolo Young, Vincent Young

Dr. Kent Udell

The annual NASA Robotic Mining Challenge tasks teams with building robots capable of traversing and mining simulated Martian terrain. The competition goal is to utilize automation and sensing alongside mechanical systems to harvest icy regolith (gravel) from beneath the planet surface. The focus of the senior design team in this competition is on designing a chassis that can efficiently support and integrate the three subsystems: movement, digging, and electrical. The goal is to utilize computer simulation to guide both the core chassis design and the integration design of the entire robot. We are also focusing on advanced material manufacturing, including composites and 3D printing, to reach desired strength/weight ratios. (NASA Robotic Mining Challenge Chassis Team Poster)

Team: Britt Argyle, Taylor Brereton, Dorothy Van Komen, Justin Schramm (lead), Chad Wing

Advisor: Dr. Jon Davies

DPS Skis Company has collaborated with the U to develop an automated machine to replace the existing manual router system. DPS Skis uses a manual router to remove excess material and to create an angled face on the sidewall of the ski. Product damage is caused when the router cuts deeper than is meant into the sidewall, leaving cuts and chunks out of the ski. These skis cannot be sold to customers. Inconsistency in the router process will reduce the surface finish consistency and reduce the effectiveness of the ski to move in the snow. The goals for this collaboration are to design and build a prototype of an automated ski sidewall router to eliminate product damage and improve the consistency of the router process. (Precision Automated Ski Sidewall Router Poster)

Team: Nur Ayoep, Brian Durkee, Jahaziel Hernandez, Josh Lyman (lead), Brock Rose

Advisor: Dr. Kam Leang

Backcountry skiers are the first responders after an avalanche and are encouraged to carry the equipment necessary to locate and save an avalanche victim. Currently, beacons are used to locate buried victims by communicating direction and distance to another beacon. For the best chance of survival, a victim needs to be found as quickly as possible. To speed up the searching process, we want to create a Search and Rescue drone that can autonomously fly to a victim while still having traditional beacon capabilities. The drone will navigate by interpreting beacon readings into its flight controller. This will accelerate the searching process because the drone will be able to quickly fly over hazardous terrain to the victim, while the user is free to prepare other tools to dig out a victim. (Search and Rescue Drone Poster)

Team: Matt Grayston, Alex Jensen (lead), Zachary Oliphant, Emmanuel Zamudio

Advisor: Dr. Kam Leang

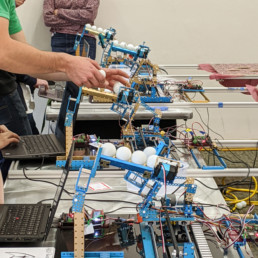

The ‘SQUARE-DANCING ROBOTS’ project aims to emulate square dancing in the form of mechanical robots that can be controlled by anyone, even people who know nothing about square dancing. The project integrates voice recognition, wireless communication, robot control and navigation. Anybody who wants to operate the system will be able to give a command and see the robots perform dance moves, giving the user the experience of being a square dance caller, with the goal being to generate interest in square dancing among the general public. There will be four robots operating simultaneously on the dance floor responding to users’ calls. Robots receive the command and create a Bezier curve defining the path of travel. Errors are correcting for using image processing of the dance floor and linearized feedback control. Come check us out on Design Day and try for yourself! (Square Dancing Robots Poster)

Team: Yousef Alsanea, Nate Baum, Adam Ely, Jeff England (lead)

Advisor: Dr. Rebecca Brannon

The Jewish Community Center uses stop watches and paper to compile their Swim Meet Data (final times, disqualifications, etc.). Our objective is to simplify this process by creating an automated timing system that will record all the information necessary to shorten their work after a Swim Meet is complete. The system requires accommodating swimmers ages 5 to 15, meaning some younger swimmers don’t have the physical capacity to trip a commonly used touch pad. The system also needs to be mobile as some races start at different ends of the pool. The final system is wireless timers connected to a receiver that can be used on any PC. The receiver can send a synchronized start signal to each timer, eliminating the possibility of missed starts. Each timer sends back to the receiver a final time that is allocated to a spreadsheet for compilation and scoring. (Swim Meet Timing and Scoring Poster)

Team: Colby Bird, Kyle Cook, Bradford McAllister (lead), Jason Mulqueen, Shane Tidwell

Advisor: Dr. Mark Fehlberg

With increases in ophthalmological surgical demands and recent advancements in technology, greater precision in eye surgery is expected, but not currently found. To address this problem, a telerobotic eye surgery device capable of high precision has been created to perform surgical procedures via remote control. The robot is mounted to patients’ heads to move directly with the patient. However, patients’ movements create a reactive force between the robot mount and the pillow they lie on. These forces dislocate the robot relative to the eye of the patient. Resultatively, precision of the robot and accuracy of the surgical procedure is reduced significantly.

Our team decided to solve this problem by re-designing the headrest that is currently used during surgery. It uses a configuration of constant force springs attached to a baseplate, upon which the head rests. This allows head motion with minimal resistance from the headrest. Facilitating head movement with minimized resistance will reduce reaction forces on the robot mount, and thereby eliminate relative motion caused by those forces. (Telerobotic Eye Surgery Headrest Poster)

Team: Michael Bowcutt, Stefan Dancy (lead), Cody Farnsworth, Jimy Pena

Advisor: Dr. Jake Abbott

While many people are familiar with photovoltaic (PV) solar panels, thermophotovoltaic (TPV) technology has only recently begun to receive the same interest and attention. Still in the early stages of research and development, TPV technology has the potential to far surpass solar PV’s efficiency when it reaches maturity. TPV devices work the same way as solar PV cells–the key difference between the two technologies is the radiation source. Solar PV cells convert radiation emitted by the sun, while TPV devices convert longer wavelength (lower energy) radiation emitted by a high temperature terrestrial source. As TPV devices capitalize on radiation emitted by a terrestrial source, they are ideal for waste heat recovery applications. Examples range from fossil fuel burners to sunlight to a nuclear fission reaction.

The purpose of our project is to produce electricity from heat using a TPV cell. The main problem we plan to tackle is maintaining a high temperature difference between a hot intermediate layer and the TPV cell using the sun as our heat source. While TPV cells have been shown to generate electricity in controlled laboratory settings, there has been little development outside of that environment. We plan to take the first steps toward taking this technology outside of the laboratory and creating a fully-packaged system for commercial use. (Thermophotovoltaic Device Poster)

Team: Spencer Donovan, Jacob Harwood, Trent Meisenheimer, Daniel Milovich (lead), Lindsay Walter

Advisors: Dr. Mathieu Francoeur, John DeSutter

One in ten adults in the U.S. lives with a physical disability, with about 30 million Americans having difficulty walking and climbing stairs. Beyond rehabilitation, people living with physical disability are prescribed passive assistive devices, such as braces and orthoses. Recent technological improvements in batteries, motors, and embedded systems have enabled the development of a new class of assistive devices, such as powered exoskeletons and bionic prostheses, which promise to restore a more natural movement ability by actively powering and controlling movements. The Bionic Engineering Lab headed by Assistant Professor Tommaso Lenzi has charged the team with developing a simulation framework to co-optimize electro-mechanics, structural, and ergonomic components of a powered knee exoskeleton. From this framework the team has designed and constructed an alpha prototype of a fully actuated knee exoskeleton with the target to replicate gait motion. The exoskeleton will be used to assist the impaired by providing the torque and range of motion needed to complete tasks such as walking, climbing stairs, and standing up from a sitting position. (Utah ExoKnee Poster)

Team: Abigail Campbell, Polly Creveling, Nate Luttmer, Sergei Sarkisian (lead)

Advisor: Dr. Tommaso Lenzi

Essential tremor (ET) is the most common movement disorder in adults age 65 and older with a prevalence of up to 9.0%. This represents nearly 2.5% of the U.S. population. With an aging population, there is an urgent need for new technologies to address ET. ET most commonly affects the upper limbs and is often highly disabling. Completing activities of daily living (ADL) (eating, bathing, dressing, etc.) can become increasingly more difficult for persons with ET, often resulting in the inability to independently live without assistance.

Previous efforts have been only modestly successful in reducing ET while restoring multiple ADL functions. For this reason, the focus of the project is on designing a device to reduce ET across multiple activities. The design consists of a pump circulating water through a tubing coil wrapped around the user’s forearm. The water produces an angular momentum to provide impulse resistance to any force that attempts to change the vector’s direction. Therefore, providing a gyroscopic effect to stabilize the forearm and hand. (Wearable Tremor Dampening Device Poster)

Team: Irsyad Badri, Kory Cross, Mikaela Hayward, Hyrum Peterson, Quincy Stevens

Advisor: Dr. Andrew Merryweather