Congratulations to our team of undergraduate students for winning the 2023 IEEE/EPS ASME K-16 Student Heat Sink Design Challenge. This yearly competition gives students the opportunity to design an additively manufactured aluminum natural convection heat sink that provides maximum performance. These heat sinks are designed to operate at as low a temperature as possible for minimal cost. They also need to leverage the possibilities and advantages of additive manufacturing (metal 3d printing). This year’s competition focused on a natural convection heat sink in a vertical enclosure.

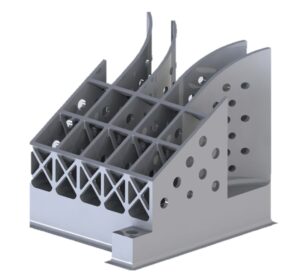

This year’s team consisted of Preston Bodily, Taylor Cox, Chandler Elliott, Zach Julien, and Xander Lehnardt. They were co-advised by Dr. Samira Shiri, Dr. Tianli Feng, and Dr. Sameer Rao. Their preliminary process consisted of brainstorming, simple testing, and iterating on designs using a SOLIDWORKS simulation to predict the Figure Of Merit (FOM). After trying multiple designs, the team settled on the X Tent, which optimized disruption of the convective boundary layer and supply of cold ambient air.

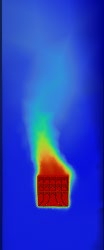

From there, the team focused on reducing mass and decreasing the temperature. The group shifted to a more rigorous testing method using ANSYS Fluent to better estimate and confirm the prediction of FOM. This included defining a mesh based on their 3D model and environment, setting up materials and boundary conditions, and gathering the final data. With this information, the team found unnecessary mass to remove and extended surfaces to improve natural convection.

The Utah team emerged as the initial semi-finalists in the ASME K 16 heatsink contest. This selection was made by a panel of experts from academia and industry based on a technical paper authored by the students. Semi-finalists earned the opportunity to proceed with the metal (aluminum) 3D printing of their heatsink by GE Additive. Once the 3D printing phase was completed, the heatsinks were subjected to a series of experimental tests to measure their FOM, completed by the University of Southern Denmark. Based on the results and the merits of the design process used by the Utah team, they were chosen as finalists. In the final contest stage, the Utah team competed with Texas A&M and the TU Berlin teams at the ITherm conference. The Utah team was ultimately chosen as the winner, based on a combination of the experimentally determined FOM, effective use of additive manufacturing, and presentation skills at the conference. This is the second time an undergraduate team from the University of Utah Mechanical Engineering Department has won the student heat sink design competition, the first time being in 2020.